Amandla elanga angumthombo ongashi wamandla avuselelekayo esintwini futhi anendawo ebalulekile kumasu esikhathi eside wamandla amazwe emhlabeni jikelele. Ukukhiqiza amandla efilimu ezacile kuncike kufilimu emincane yama-solar cell chips alula, azacile futhi aguquguqukayo, kuyilapho ukukhiqizwa kwamandla e-crystalline silicon kunamandla aphezulu okuguqula amandla, kodwa amaphaneli kufanele abe aminyene ngokwanele. Ngakho-ke namuhla sigxile ebuhleni nasebubini bokukhiqiza amandla efilimu emincane kanye nokukhiqizwa kwamandla e-crystalline silicon.

I. Izinzuzo zokuphehla amandla efilimu emincane

Ibhethri lefilimu elizacile elinezinto ezincane, inqubo yokukhiqiza elula, ukusetshenziswa kwamandla okuncane, ukukhiqizwa okuqhubekayo kwezindawo ezinkulu, futhi lingasebenzisa izinto ezingabizi kakhulu njengengilazi noma insimbi engagqwali njenge-substrate. Amabhethri efilimu emincane manje asungule izindlela ezihlukahlukene zobuchwepheshe, kuhlanganise ne-CIGS (i-copper indium gallium selenide) ubuchwepheshe be-solar yefilimu encane, ubuchwepheshe bemojula yefilimu encane eguquguqukayo ye-photovoltaic ifinyelele amaphuzu abalulekile, futhi igebe phakathi kwezinga lokuguqulwa kwe-photovoltaic lamabhethri e-crystalline silicon liyancipha kancane kancane.

Amaseli efilimu azacile anempendulo engcono yokukhanya okuphansi futhi igebe phakathi kokukhiqizwa kwamandla osuku oluguqubele kanye nelanga lizoba mncane, okuwenze afanelekele ukusetshenziswa eziteshini zamandla ze-PV zasogwadule. Zikulungele futhi ukwakhiwa kwezindlu zokukhosela ilanga ezisekelwe ekhaya kanye nezindlu zelanga. Amaseli elanga acwebile njengezingxenye eziyinhloko zesistimu ye-photovoltaic, angaba kuhle kakhulu ukufeza ukuhlanganiswa kwesakhiwo se-photovoltaic.

II. Ububi bokukhiqiza amandla efilimu emincane

Izinga lokuguqulwa kwe-photoelectric lamaseli efilimu azacile liphansi, ngokuvamile liba ngu-8%. Ukutshalwa kwezimali kwemishini kanye nobuchwepheshe bamaseli efilimu amancane izikhathi eziningana kunamaseli e-silicon e-crystalline, isivuno sefilimu encane yokukhiqiza i-solar cell module ayilungile njengoba kufanele, izinga lokukhiqiza lamamojula we-non-/microcrystalline silicon thin film cell modules okwamanje lizungeze i-60% kuphela, amaqembu amaseli e-CIGS abakhiqizi abajwayelekile bangama-65% kuphela. Yiqiniso, inkinga yesivuno, inqobo nje uma uthola ikhwalithi efanele yemikhiqizo emincane yefilimu yefilimu izokwazi ukuxazulula inkinga.

III. izinzuzo ze-crystalline silicon power generation

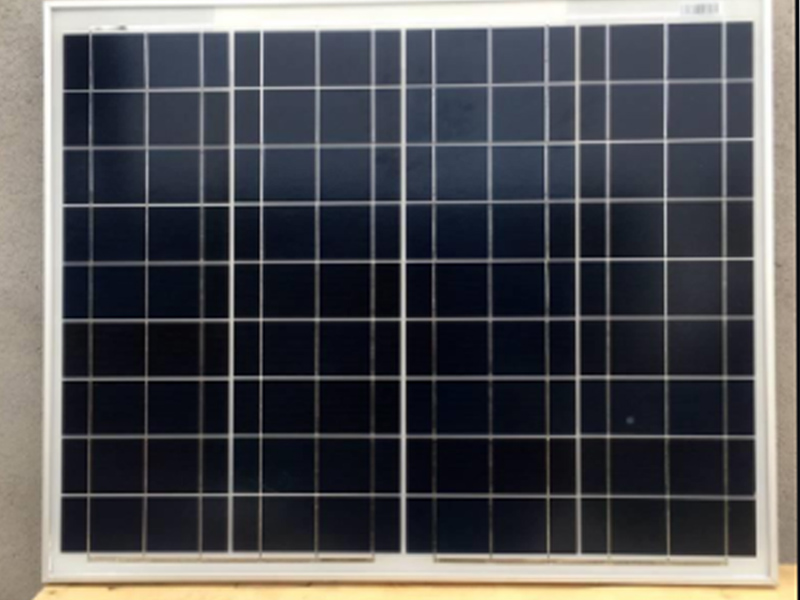

Izinga lokuguqulwa kwe-photovoltaic lamaseli e-silicon e-crystalline liphezulu, futhi izinga lokuguqulwa kwamaseli e-silicon yasekhaya lifinyelele ku-17% kuya ku-19%. Ubuchwepheshe bebhethri ye-crystalline silicon sebukhule kakhudlwana, amabhizinisi awadingi ukuguqulwa okuvamile kwezobuchwepheshe. Ukutshalwa kwezimali kumishini yamaseli e-silicon e-crystalline kuphansi, futhi imishini yasekhaya ingavele ihlangabezane nezidingo eziningi zemigqa yokukhiqiza amaseli.

Enye inzuzo yobuchwepheshe be-silicon ye-crystalline inqubo yokukhiqiza evuthiwe. Njengamanje, abakhiqizi abaningi be-silicon cell cell be-monocrystalline bangakwazi ukuzuza izinga lokukhiqiza lika-98% noma ngaphezulu, kuyilapho izinga lokukhiqiza lokukhiqizwa kwamaseli e-polycrystalline silicon lingaphezu kwama-95%.

IV. Ukungalungi kokukhiqizwa kwamandla e-crystalline silicon

Uchungechunge lwezimboni luyinkimbinkimbi, futhi izindleko zingase zingancishiswa kakhulu. Izindleko zezinto zokusetshenziswa zishintshashintsha kakhulu, futhi eminyakeni yamuva nje imakethe yamazwe ngamazwe ibilokhu iyi-roller-coaster ride ye-polysilicon. Ngaphezu kwalokho, imboni ye-silicon iyimboni engcolisa kakhulu futhi edla amandla, futhi kunengozi yokulungiswa kwenqubomgomo.

Isifinyezo

Amangqamuzana e-crystalline silicon enziwa ikakhulukazi ngezinto ze-silicon, eziqukethe i-boron ne-oxygen silicon wafers ngemva kokukhanya kuzobonakala njengamazinga ahlukene okubola, uma kukhulu okuqukethwe kwe-boron nomoya-mpilo ku-wafer ye-silicon ekukhanyeni noma izimo zamanje zokujova okukhiqizwa yi-boron ne-oksijini eyinkimbinkimbi, ubukhulu bokunciphisa impilo bubonakala nakakhulu. Uma kuqhathaniswa namangqamuzana elanga e-silicon ecwebezelayo, amaseli elanga amancane ayifilimu ayidingi ukusetshenziswa kwezinto ze-silicon, uhlobo lwamaseli elanga e-silicon amorphous, i-zero attenuation.

Ngakho-ke imikhiqizo ye-crystalline ye-silicon solar cell ngemva kweminyaka embalwa yokusetshenziswa, kuzoba namazinga ahlukene okubola okusebenzayo, okungathinti nje imali yokukhiqiza amandla, kodwa futhi kufinyeze impilo yesevisi. Ifilimu encane yamaseli elanga njengesizukulwane sesibili semishini yokuphehla amandla e-photovoltaic esetshenziswa kabanzi emazweni athuthukile emhlabeni jikelele, intengo yayo ngempela ibiza kancane kunamaseli elanga e-crystalline silicon okwamanje, angeke anciphise, impilo ende yesevisi nezinye izici ezinqunyiwe, inani elidalwe ukusetshenziswa kwesikhathi eside lizoba phezulu.

Isikhathi sokuthumela: Dec-16-2022