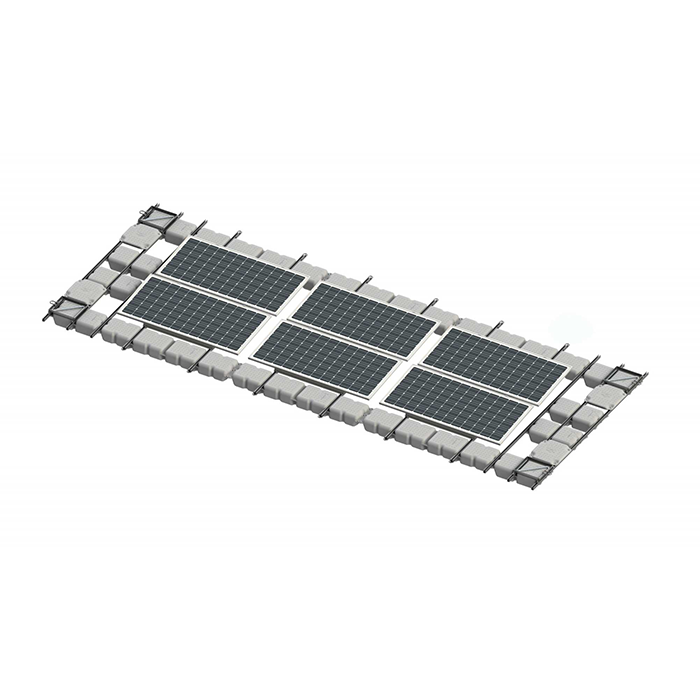

SF FLOATING SOLAR MOUNT (TGW03)

Solar First Floating PV Mounting Systems are designed for the emerging floating PV market for the installation in various water bodies such as ponds, lakes, rivers and reservoirs, with excellent adaptability with the environment.

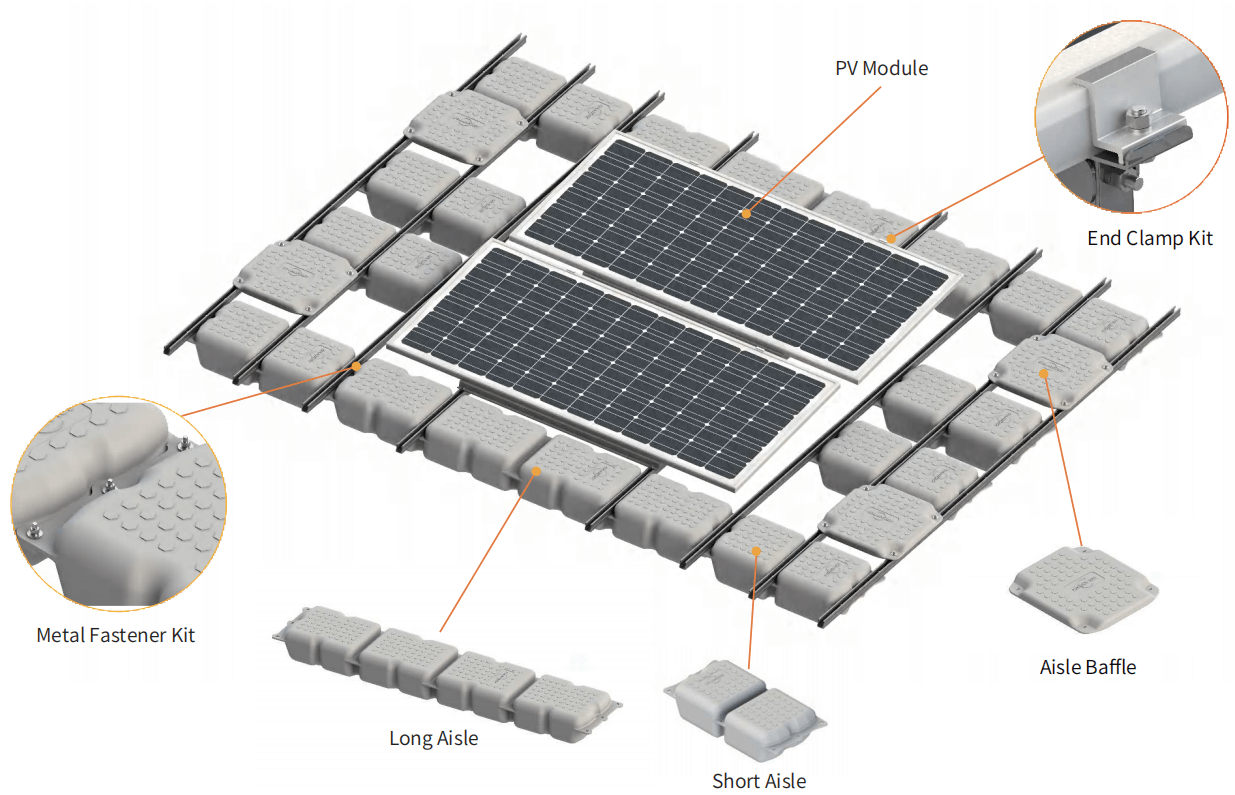

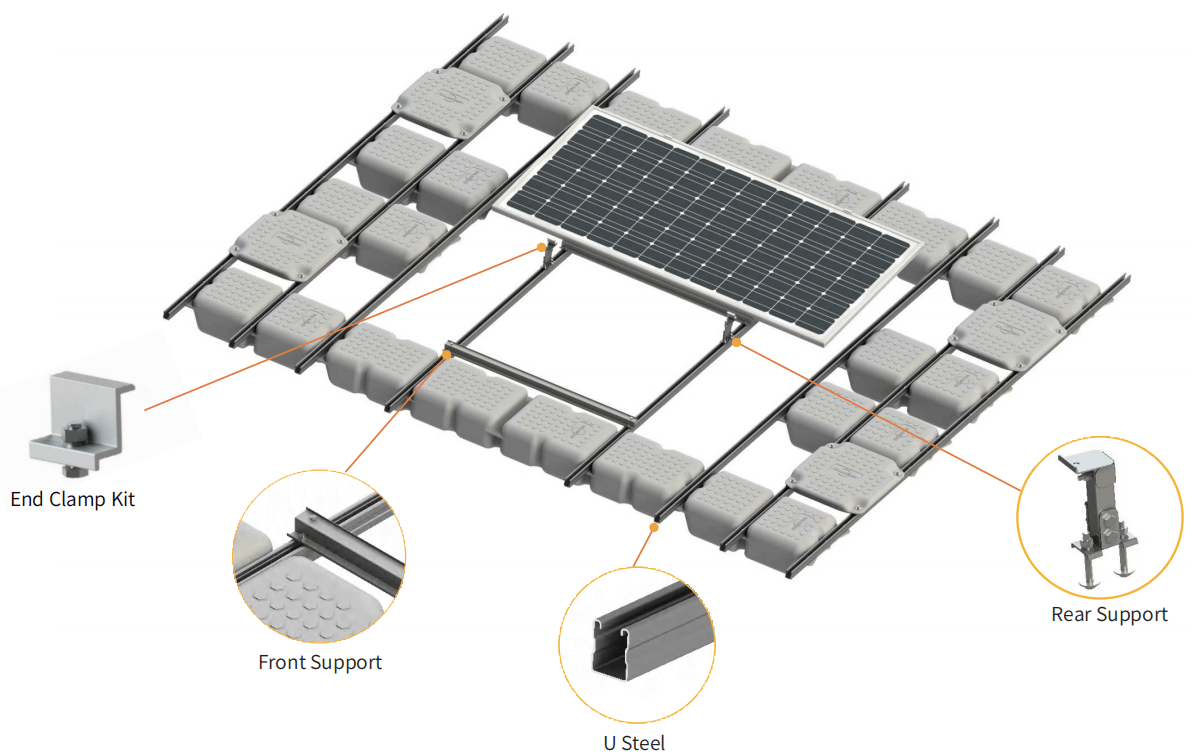

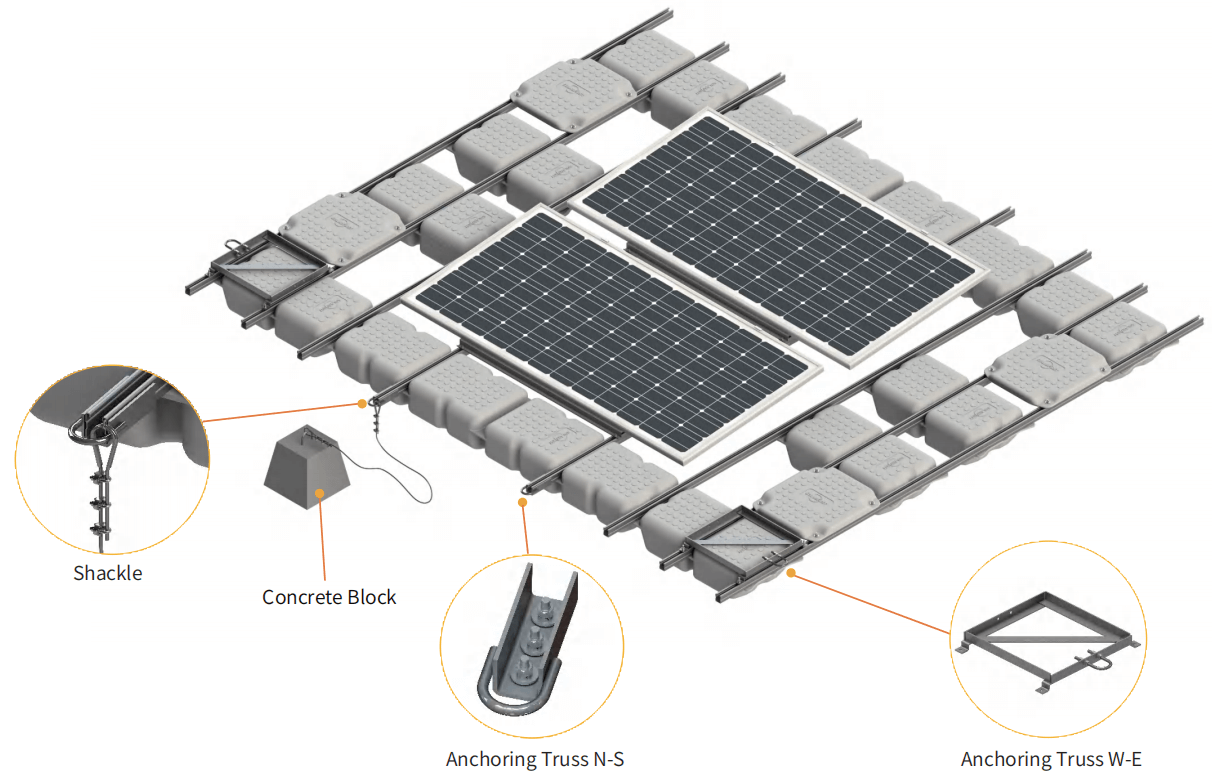

Anodized Aluminium / ZAM coated steel is used for the mounting components that makes the system durable and lightweight, thereby enabling its easy transportation and installation. Corrosion-resistant stainless steel is used for the system’s fasteners that provides good strength and heat resistance to withstand harsh environmental conditions. The bearing in connection point forms a hinge joint and enable the whole floating platform float up and down along with waves, which reduce the impact of waves on structure.

Solar First's floating mounting systems have been tested in wind tunnel in its performance. The designed service life is more than 25 years with 10 years product warranty.

Overview of Floating Mounting System

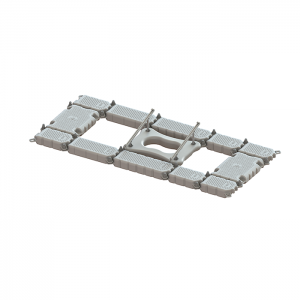

Solar Module Mounting Structure

Anchoring System

Optional Components

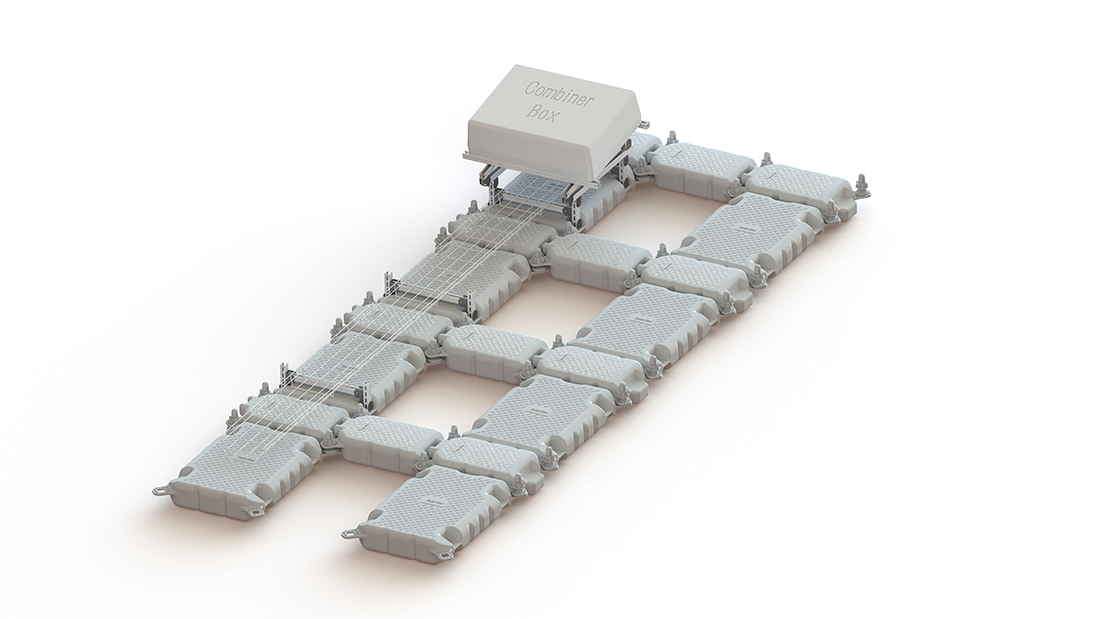

Combiner Box / Inverter Bracket

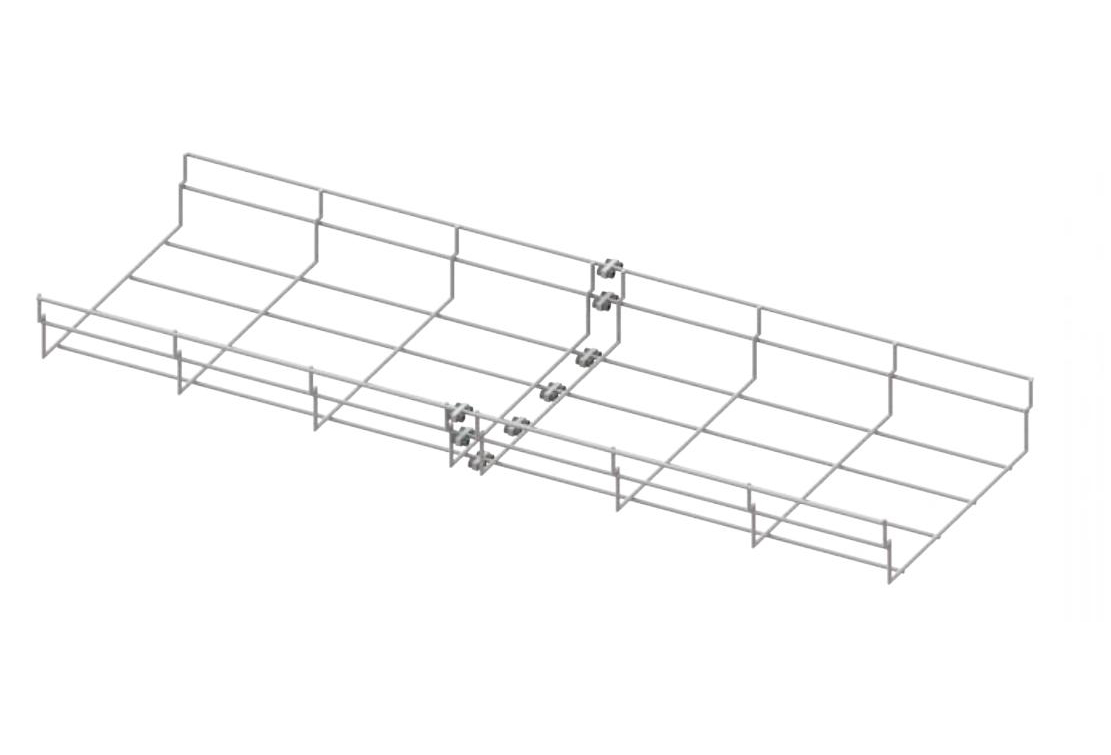

Straight Cable Trunking

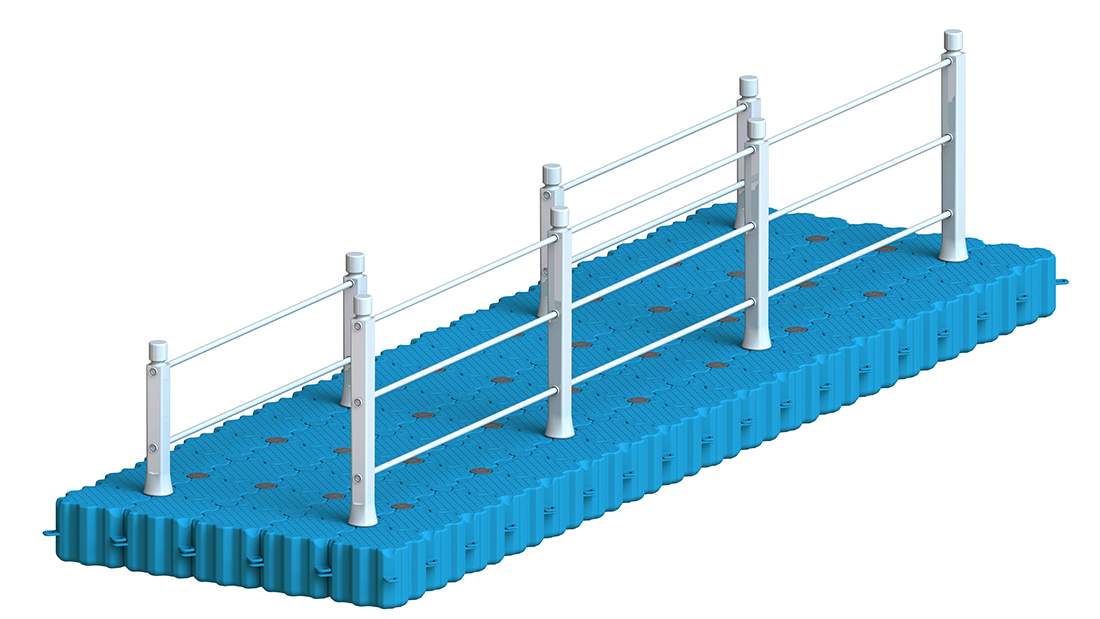

Visiting Aisle

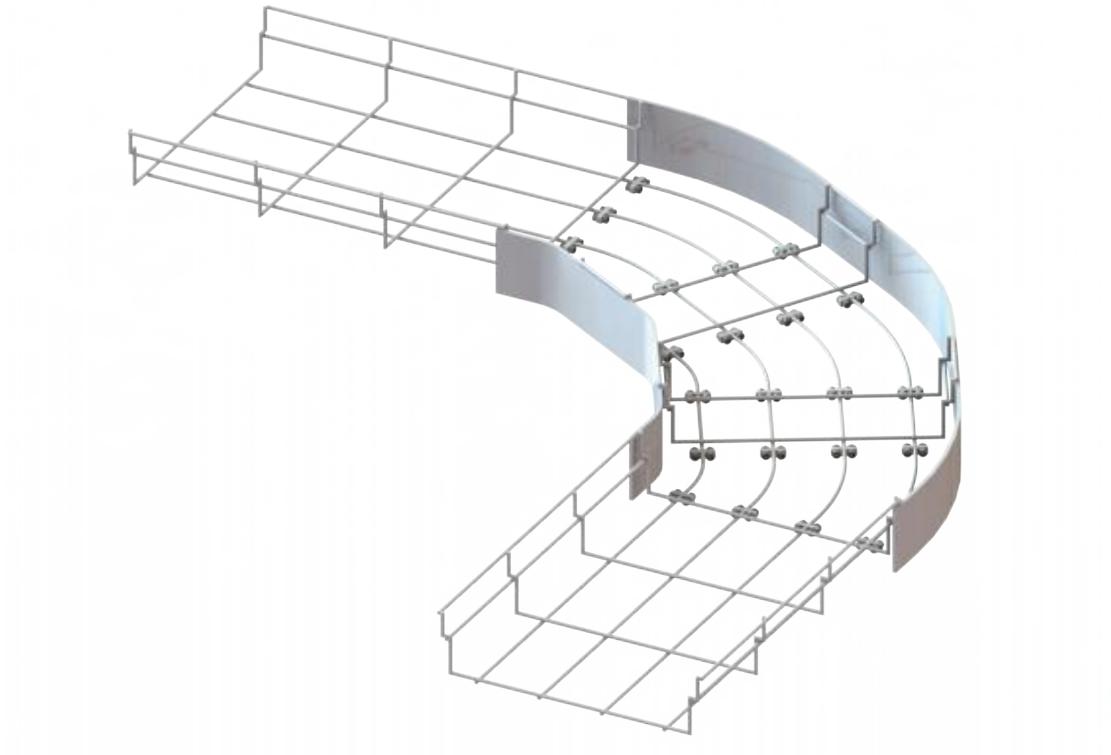

Turning Cable Trunking

| Design Description:

1. Reduce water evaporation, and utilize the cooling effect of water to increase the power generation. 2.The bracket is made of aluminum alloy or steel for fireproof. 3.Easy to install without heavy equipment; safe and convenient to maintain. |

|

| Installation | Water Surface |

| Surface Wave Height | ≤0.5m |

| Surface Flow Rate | ≤0.51m/s |

| Wind Load | ≤36m/s |

| Snow Load | ≤0.45kn/m2 |

| Tilt Angle | 0~25° |

| Standards | BS6349-6, T/CPIA 0017-2019, T/CPIA0016-2019, NBT 10187-2019, GBT 13508-1992, JIS C8955:2017 |

| Material | HDPE, Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| Warranty | 10 Years Warranty |