-

5MWp Floating Photovoltaic Power Station Project in JapanProject information

5MWp Floating Photovoltaic Power Station Project in JapanProject information

68KWp Floating Photovoltaic Power Station ProjectCapacity: 68KWpProduct: Solar Floating Mounting SystemConstruction time: 2017

01 Product Description

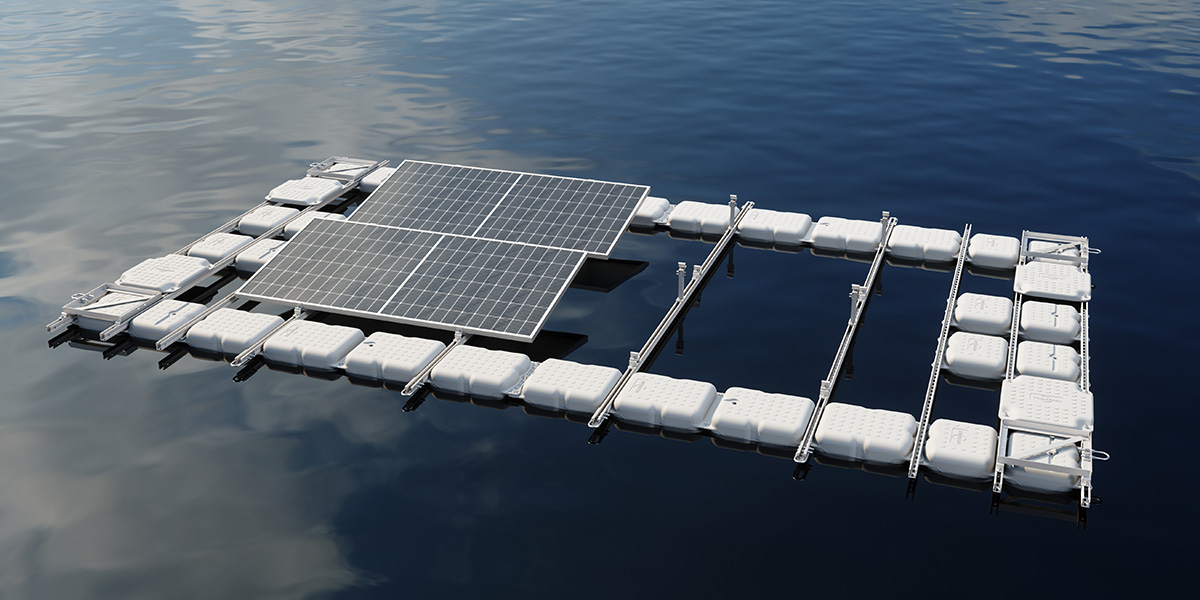

Solar First's floating PV system transforms underutilized water surfaces into clean energy assets through its groundbreaking continuous-row configuration. This design enables flexible expansion from 2 to 5 connected rows while cutting material usage and project costs. The reduced physical footprint allows denser module arrangements, maximizing generation capacity within limited aquatic areas. Our SF-TGW02 solution delivers optimal performance in protected waters with mild climates, offering exceptional ROI where land availability is constrained.

As viable land becomes increasingly scarce, our floating technology presents a sustainable alternative that harmonizes energy production with environmental stewardship. The system creates multiple ecological benefits: conserving water resources through reduced evaporation, improving water quality by limiting algae proliferation, and maintaining pristine conditions through food-safe materials. With simplified cleaning requirements and completely recyclable components, this solution establishes new standards for Eco-conscious solar development while providing reliable power generation across lakes, reservoirs and protected water bodies.

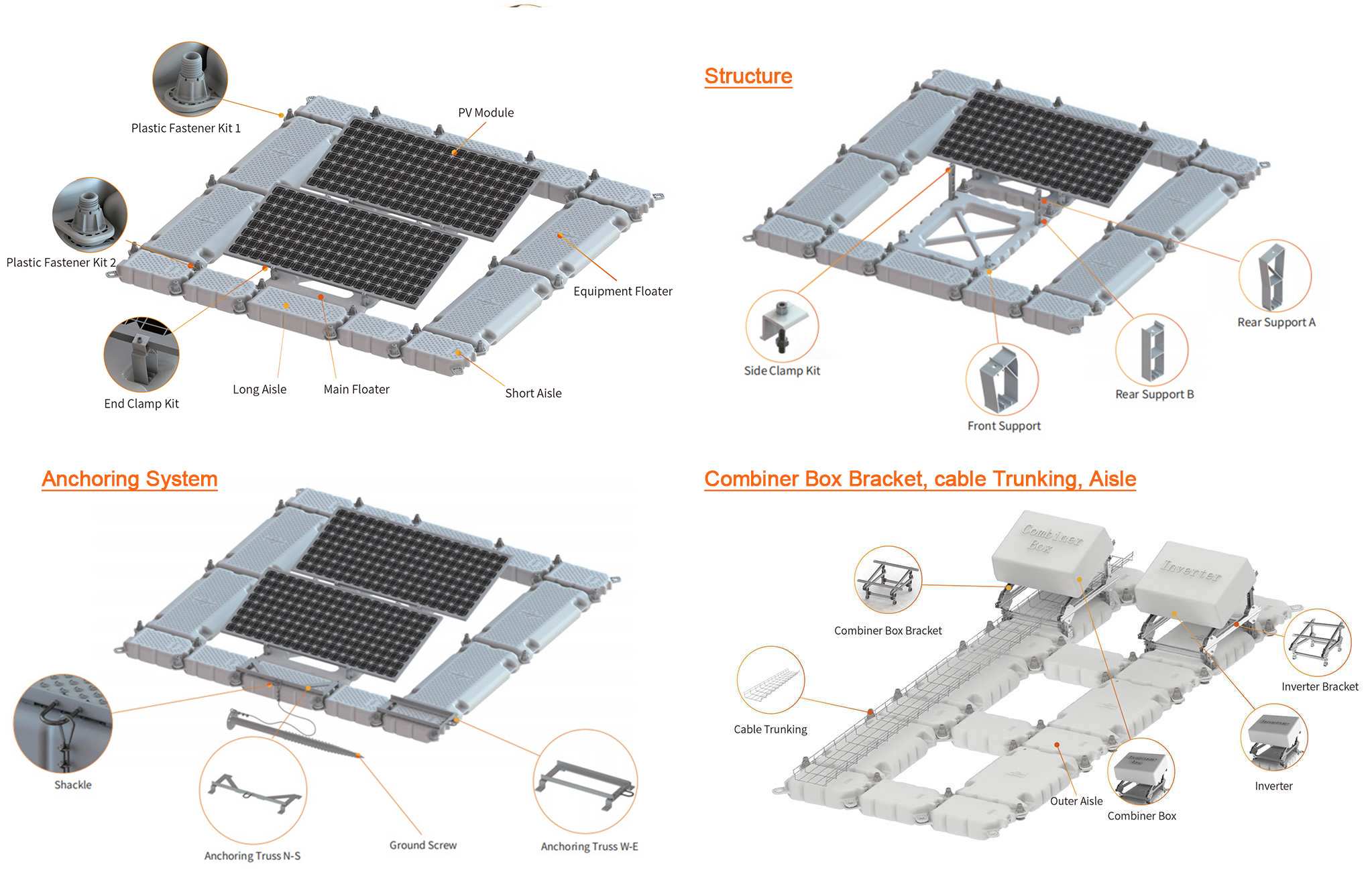

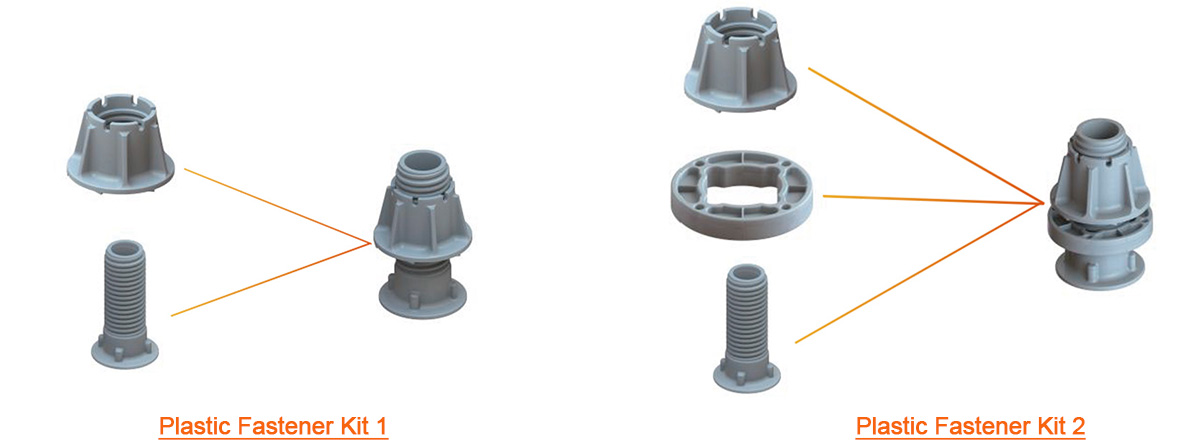

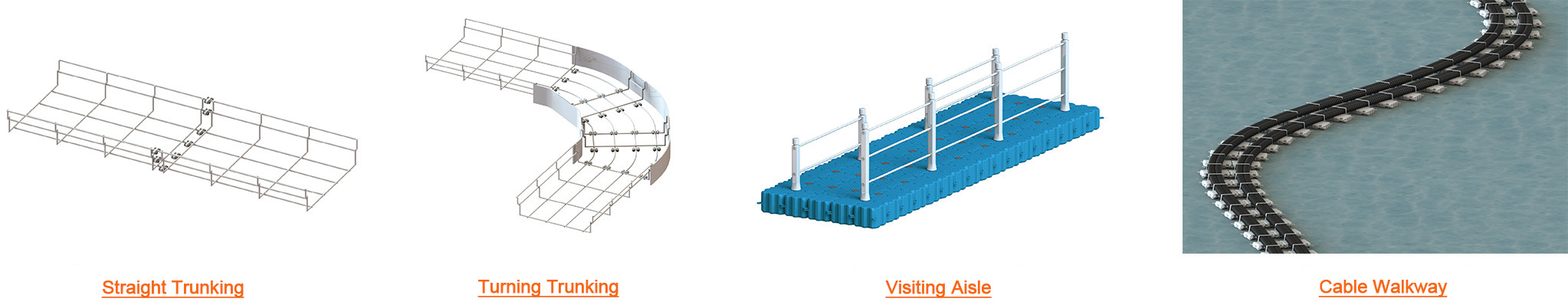

02 Accessory schematic diagram

03 Product Components

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Installation Site | Water Surface |

| Surface Wave Height | ≤0.5m |

| Surface Flow Rate | ≤0.5m/s |

| Wind Speed | ≤42m/s |

| Snow Load | <1KN/m² |

| Tilt Angle | 0-20° |

| Standard | GB50009-2012, EN1990:2002, ASCE7-05/ASCE7-10, AS/NZS1170, JIS C8955:2017 |

| Material | HDPE, Anodized Aluminum AL6005-T5, Stainless Steel SUS304, Zn-Al-Mg Coated Steel |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Fishery photovoltaic complementary project: Fish ponds and aquaculture lakes, forming a three-dimensional model of "upper layer power generation and lower layer aquaculture"

✔ Offshore and Marine ranches: Anti-corrosion floating bodies must be adopted

✔ Industrial water areas: industrial wastewater ponds, sedimentation areas in mining areas

✔ Reservoirs: Mainly floating type (such as the deep water area in the middle of the reservoir) or pile foundation fixed type (shallow water area near the shore)

✔ Urban ecological landscapes: rivers, landscape lakes, and regulating tanks of sewage treatment plants

06 Professional technical services

▶ Solution design and structural analysis:

Provide layout drawing, customized solution drawing, load calculation reports (including wind load, snow load, buoyancy analysis) or assembly drawing.

▶ On-site survey:

Engineers conduct on-site survey water and soil conditions with local hydrologic and soil investigation professionals.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site installation training to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :