01 Product Description

Engineered for durability on both residential and commercial tile roofs, this mounting system is constructed from high-performance materials, including anodized structural aluminum and stainless steel components, for exceptional corrosion resistance.

It features a comprehensive selection of tile hooks, meticulously designed to conform to a wide variety of profiles such as imbricate tiles, flat tiles, slate tiles, Spanish tiles, Roman tiles, and stone-coated metal tiles. These hooks install discreetly beneath the tiles without any surface penetration. For challenging installations, adjustable hook designs are available to ensure a secure and adaptable fit.

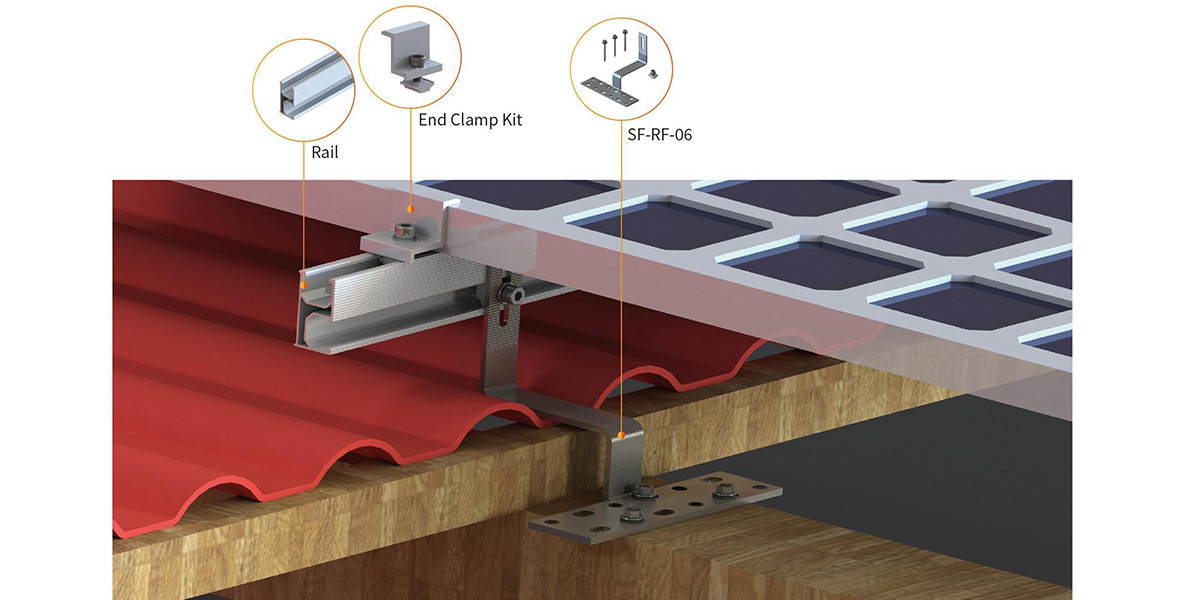

02 Accessory schematic diagram

03 Product Components

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Tile Roof |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | Parallel to Roof Surface |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50429-2007 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Traditional residential tiled roofs (clay/cement tiles)

✔ Commercial building SLATE tile roof

✔ Stone-faced metal tile ancient-style buildings

06 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :