Standing seam roof clamps are non-penetrating devices used to securely attach various accessories, such as solar panels, snow guards, and fall protection systems, to standing seam metal roofs without drilling or damaging the roof surface.

Color :

Natural silver/ black(Colored according to customer requirements)Material :

Anodized Aluminum 6005 T5, Stainless Steel 304Certification :

ISO,SGS,CE01 Product Description

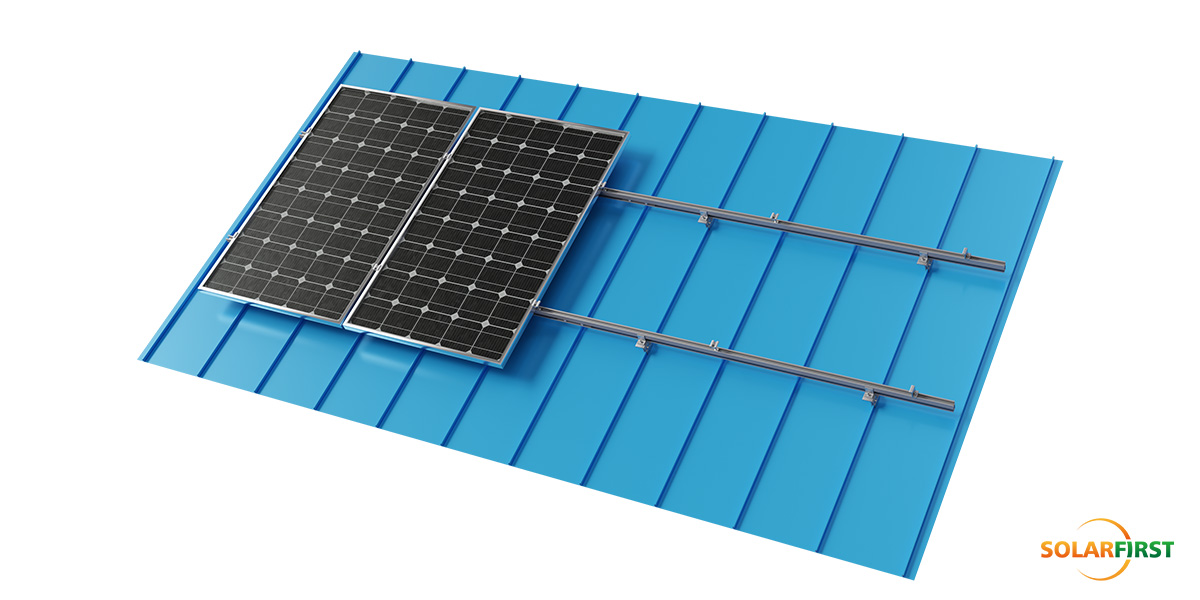

Engineered for standing seam metal roofs, this robust mounting system provides a secure, non-penetrating racking solution.

Its design prioritizes installation efficiency and cost-effectiveness. The lightweight aluminum components minimize structural load, while specialized clamps are tailored to fit various standing seam profiles. For projects requiring elevated mounting, the clamps are compatible with L-foot brackets to achieve the optimal solar module elevation and positioning.

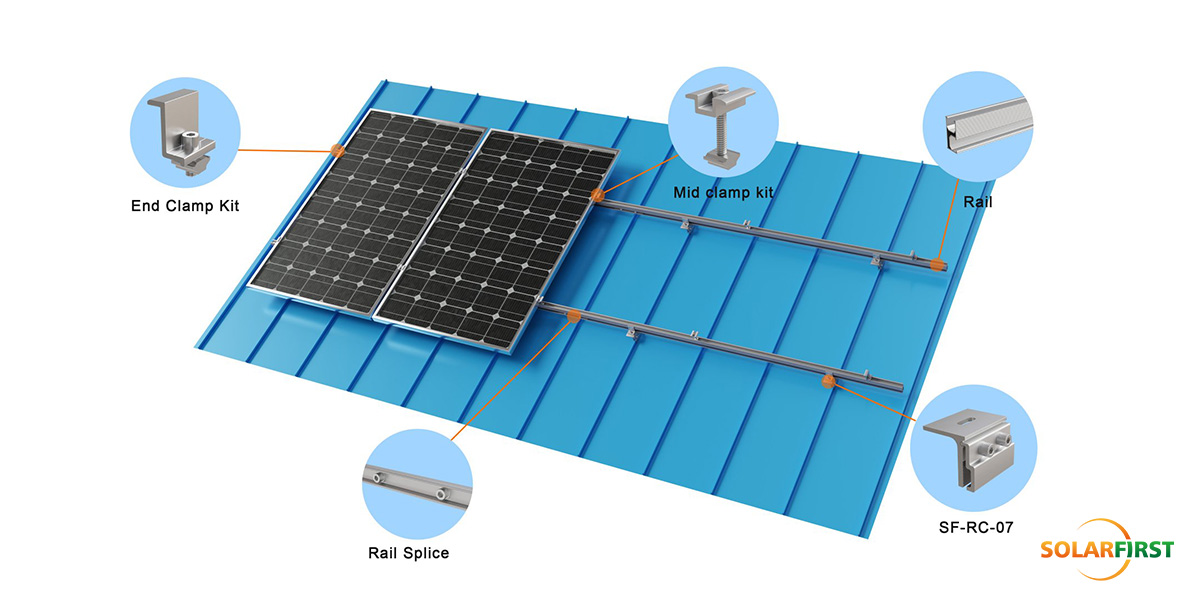

02 Accessory schematic diagram

03 Product Components

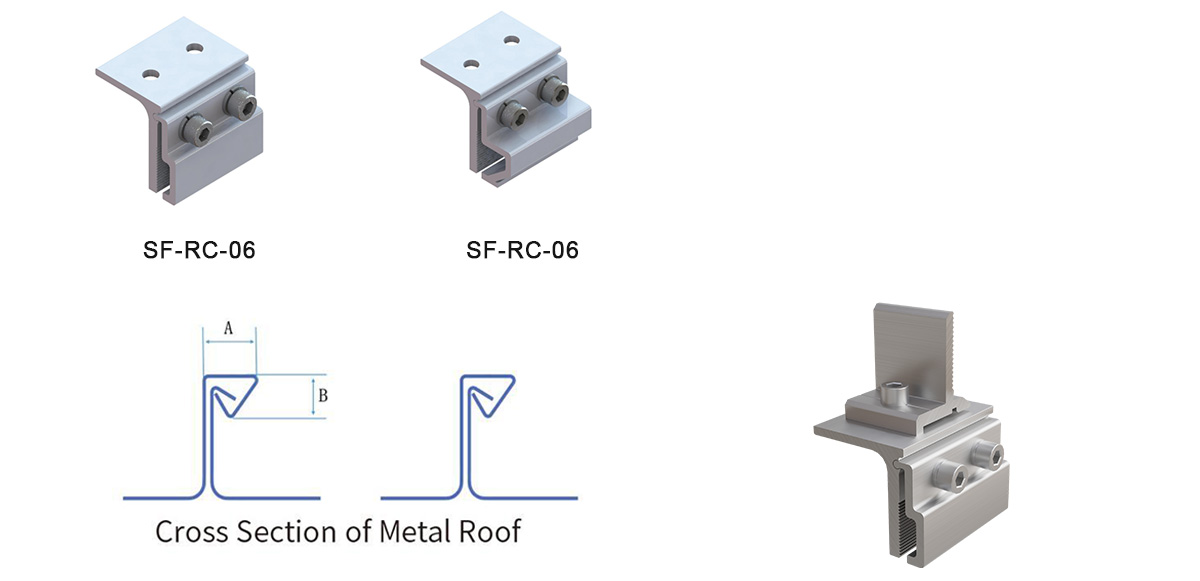

| Dimensions (mm) | A | B |

| SF-RC-06 | 8.5 | 18 |

| SF-RC-07 | 21 | 18 |

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Standing Seam/Seam Lok metal roof |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | Parallel to the roof |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50429-2007 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Manufacturing factory: Roof of automotive/electronic factory buildings

✔ Cold chain logistics center: Large warehouse roof

✔ Agricultural greenhouse upgrade: Light steel frame greenhouse

06 Key Features

• Non-Penetrating Design:

Clamps grip the raised seam of the metal roof, eliminating the need to pierce the metal sheeting and ensuring the roof remains waterproof.

• Material:

They are typically made from durable, corrosion-resistant materials like high-grade aluminum (Al6005-T5) or stainless steel (SUS 304), suitable for long-term outdoor use and harsh weather conditions.

• Versatility:

A wide range of clamps are available to fit different standing seam profiles, including T-shaped, bulb, and various snap-lock or mechanically seamed designs.

• Easy Installation:

Designed for quick and simple installation, reducing labor time and costs.

• High Strength:

When correctly matched to the roof profile and installed with the proper torque, these clamps offer significant holding strength and high load-bearing capacity to withstand wind uplift and snow loads.

07 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

08 Project Case

leave a message

Scan to wechat :