01 Product Description

This adaptable ballasted solution provides a secure, non-penetrating mount for residential and commercial concrete flat roofs.

The low-profile design inherently counters wind uplift forces, and the optional addition of a wind deflector fortifies the structure for maximum stability in challenging environments.

With a choice of 5°, 10°, or 15° tilt angles and a simple design that expedites installation, it seamlessly integrates with ancillary components like metal roof clamps and U-rails for expanded system configuration.

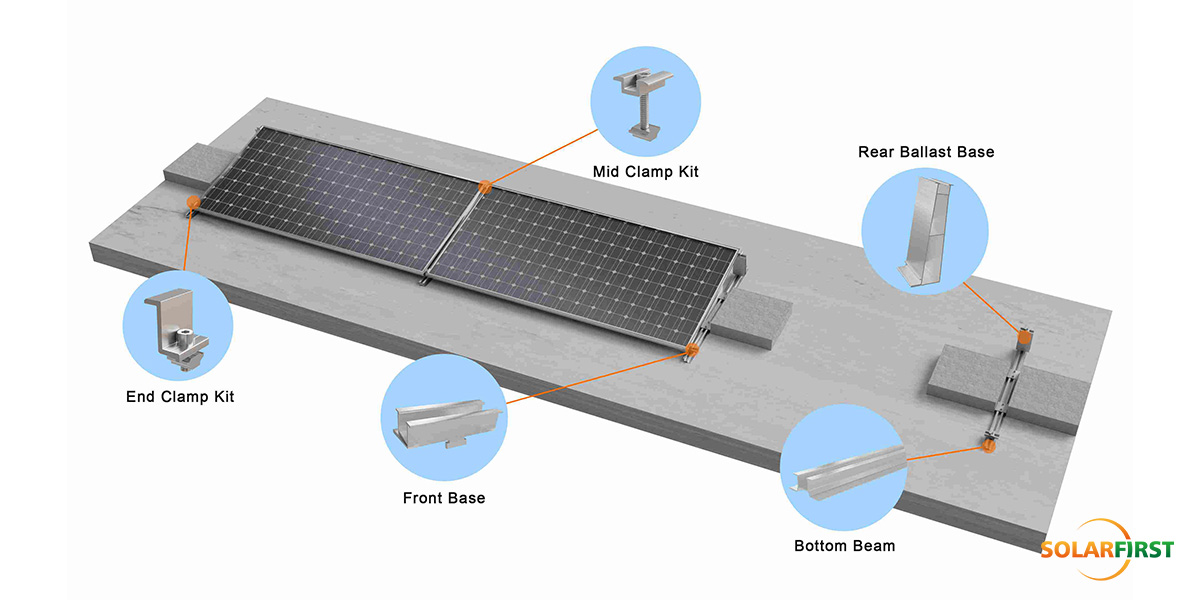

02 Accessory schematic diagram

03 Product Components

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Ground/Concrete Roof |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | 5°, 10°, 15° |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50429-2007 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Concrete flat roof for commercial buildings

✔ Cement flat roof of industrial plant

✔ Flat roof structure for public facilities

06 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :