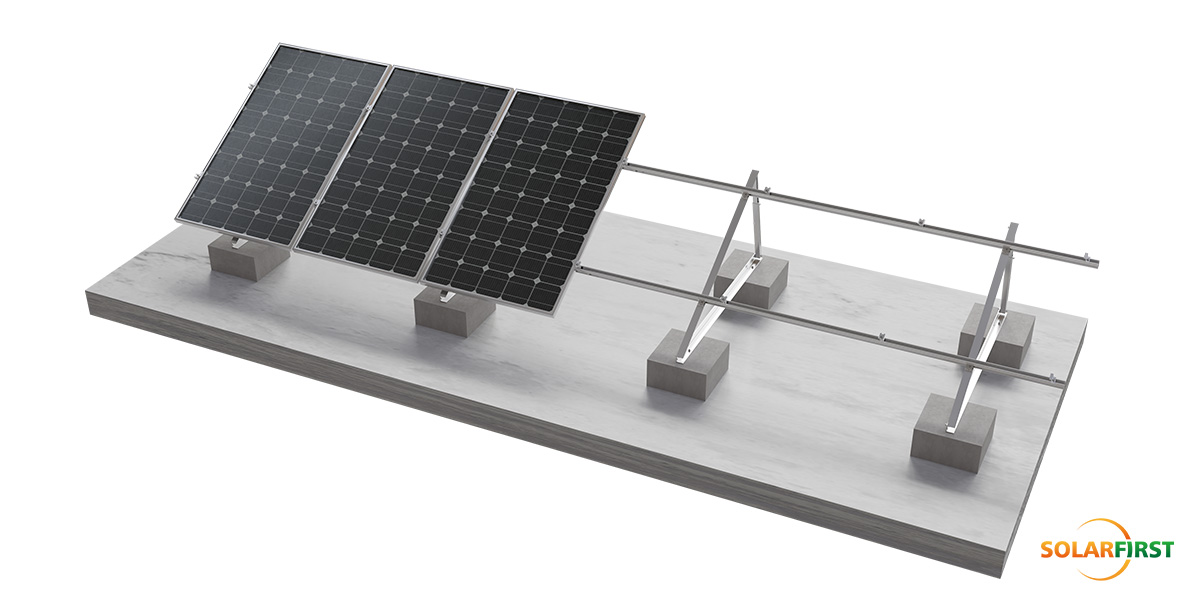

01 Product Description

Ready-to-Install Non-Penetrating Solution for Flat Roofs & Ground Mounts.

Our triangular-frame mounting system delivers unmatched speed and stability for concrete flat roof projects. Designed for quick deployment, it features customizable tilt angle range to optimize energy capture quickly and easily with our adjustable telescoping legs.

The key to its efficiency is factory pre-assembly -- the triangular brackets and clamps arrive ready for immediate installation, dramatically reducing labor time and cost. This universal design provides a single, adaptable solution for both rooftop and ground-based solar arrays.

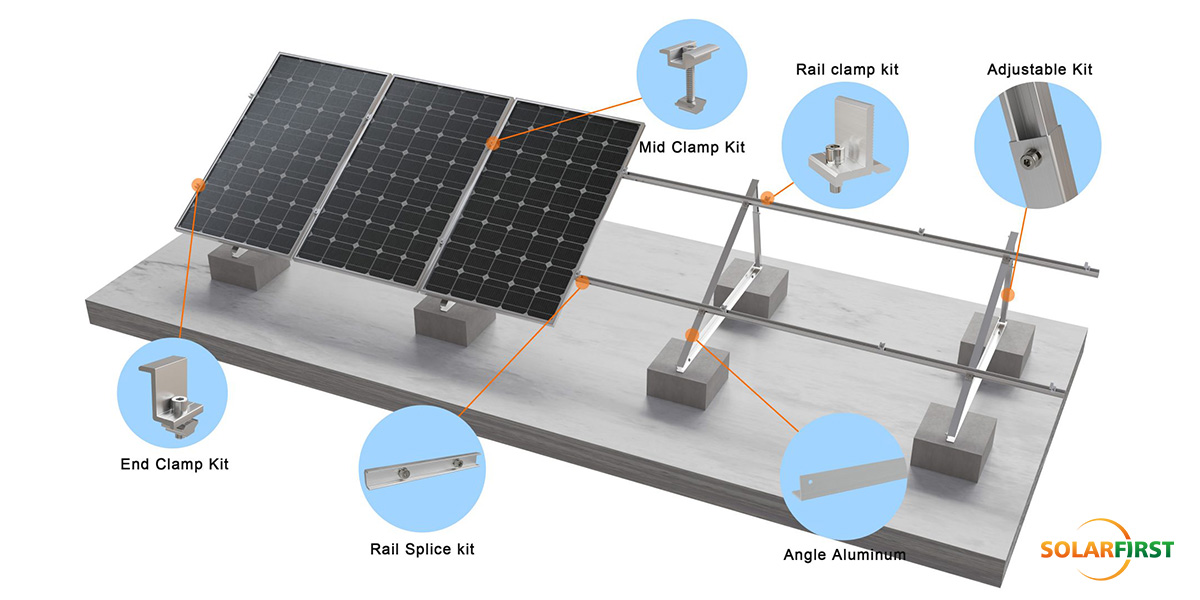

02 Accessory schematic diagram

03 Product Components

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Ground/Concrete Roof |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | 5°-60° |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Residential concrete flat roof photovoltaic

✔ Commercial building flat roof power station

✔ Ground-mounted distributed photovoltaic arrays

06 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :