01 Product Description

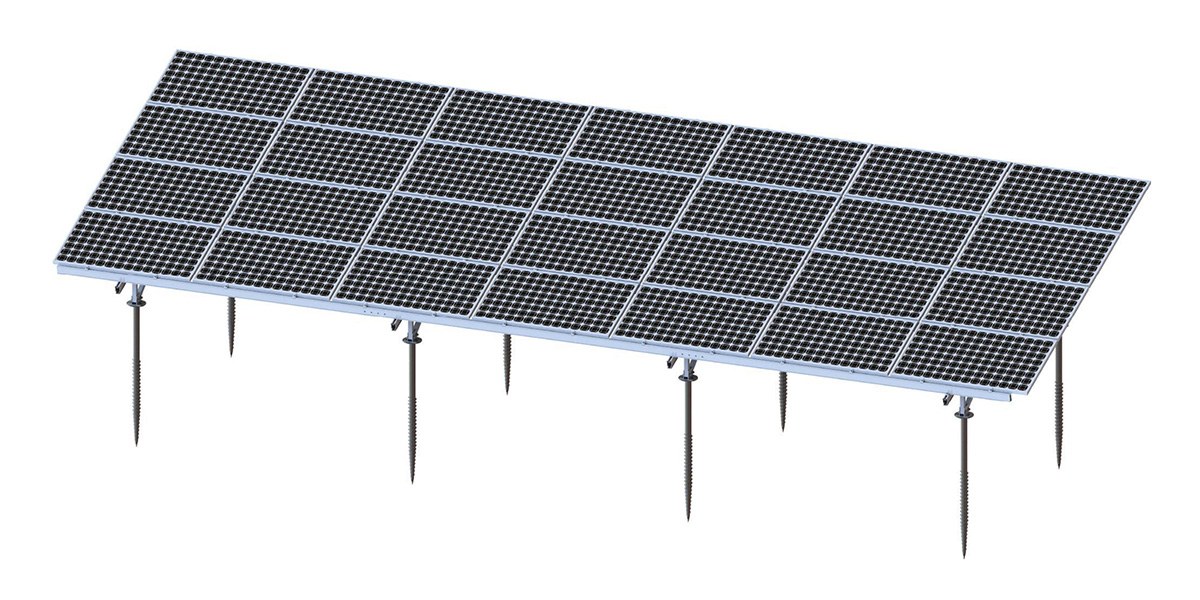

This solar panel mounting system is a highly anti-corrosion mounting structure for ground solar power project with its aluminium alloy 6005 and 304 stainless steel material .

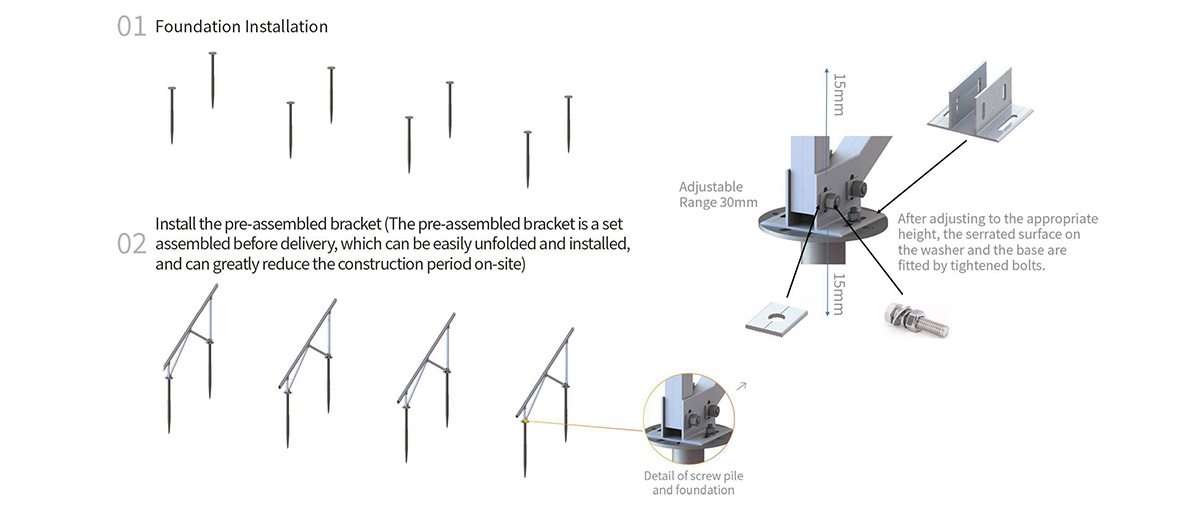

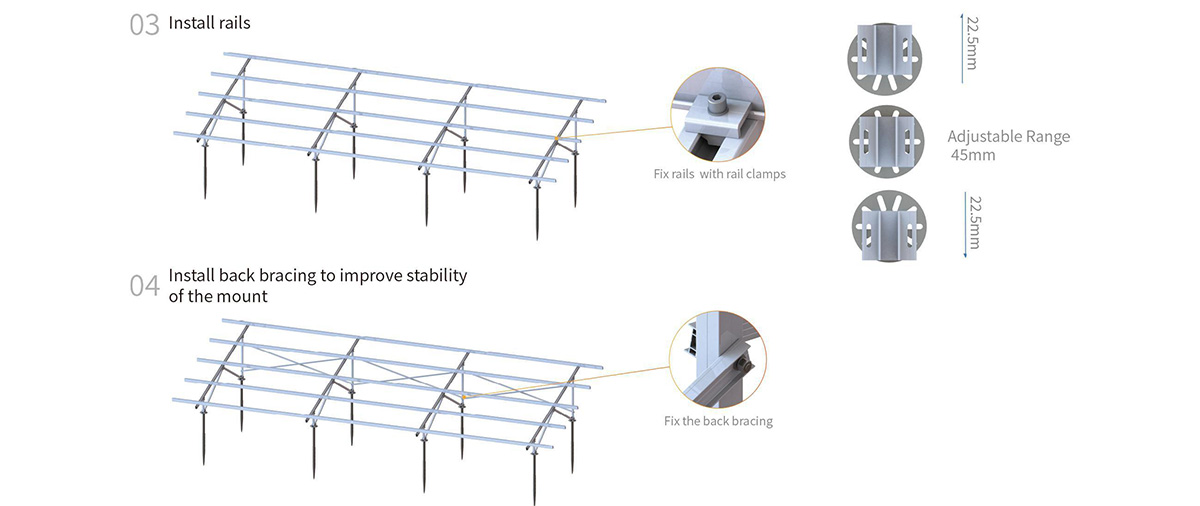

The beams and supports will be pre-assembled on the factory before delivery, to save working time on site. The special base plate design ensures adjustable range on height and front-back direction, to adapt installation site.

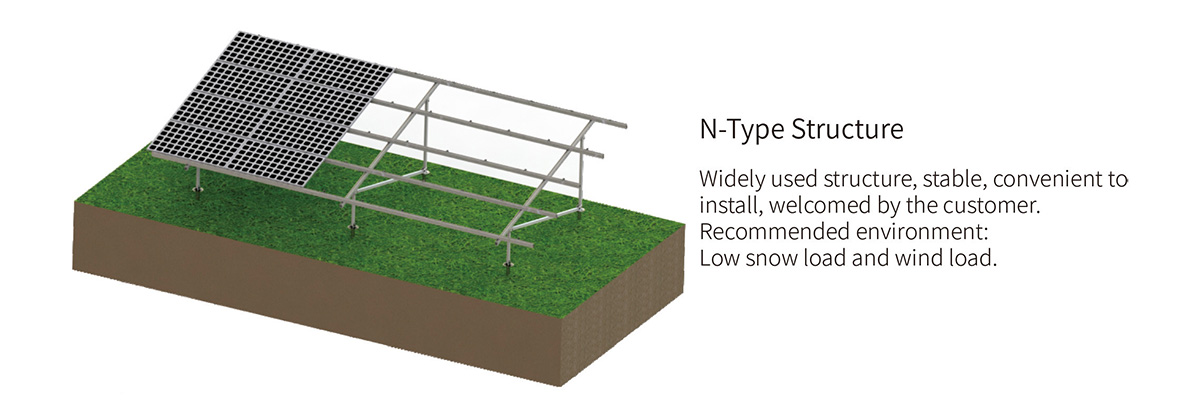

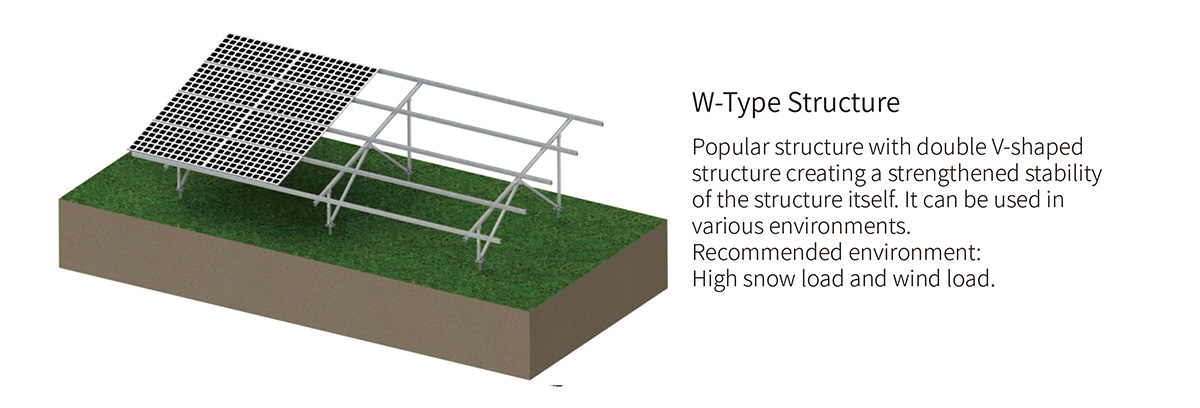

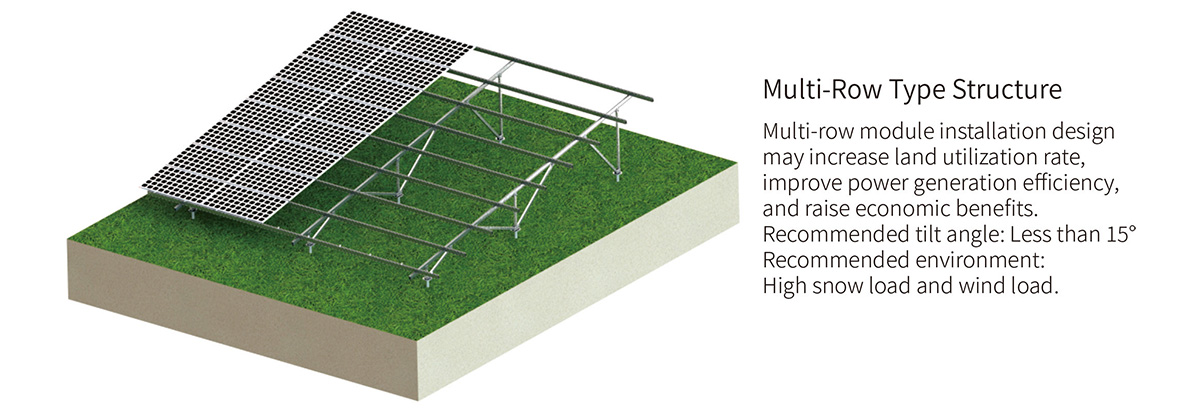

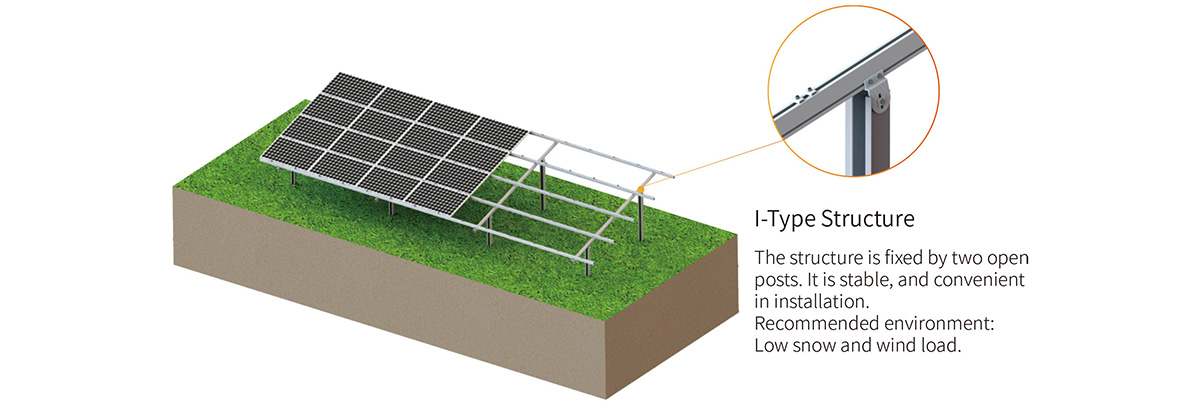

Different structure type will be chosen according to site conditions and load requirements.

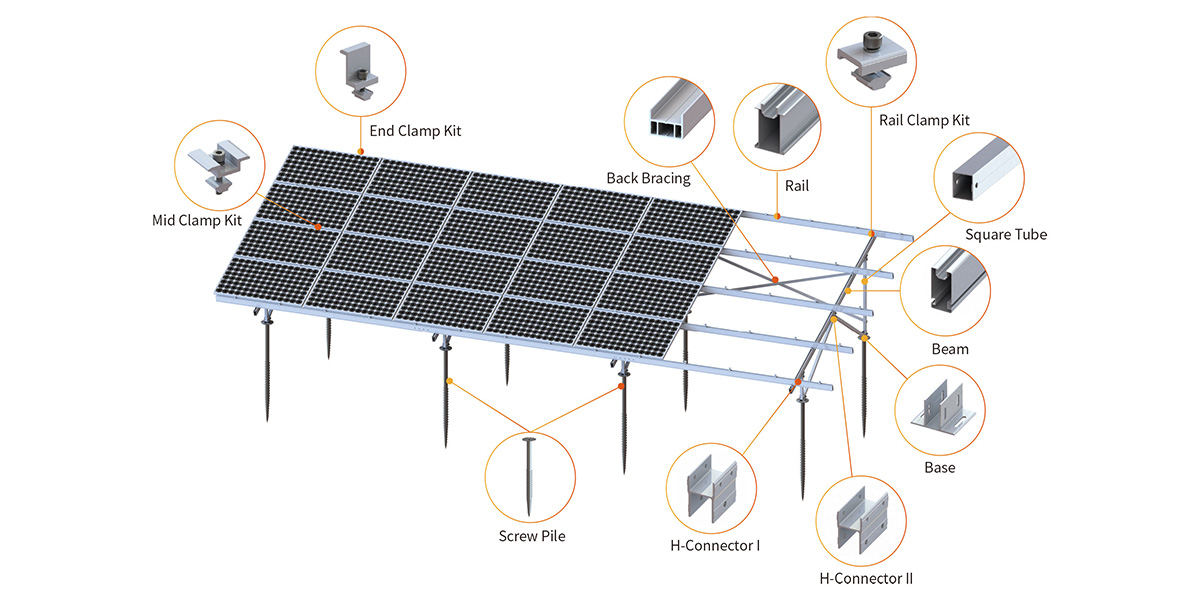

02 Accessory schematic diagram

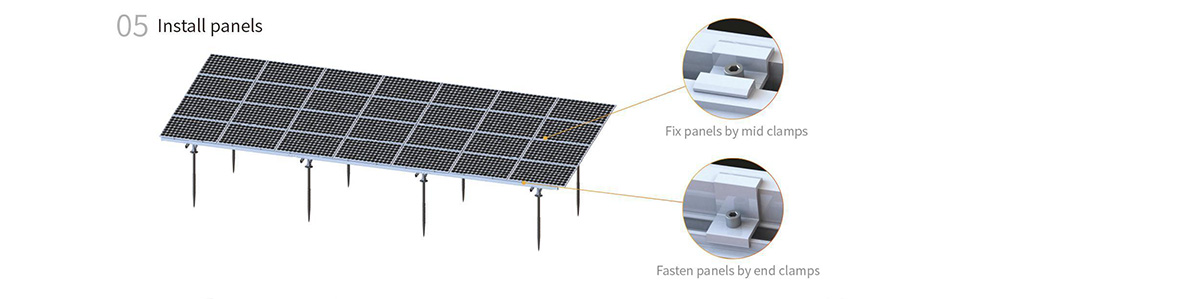

03 Structure

05 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Ground |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Foundation | Screw Pile / Concrete |

| Main material | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50017-2017 |

| standard | Anodized Aluminum AL6005-T5, Hot Dip Galvanized Steel, Zn-Al-Mg Pre-Coated Steel, Stainless Steel SUS304 |

| Warranty | 10 Years Warranty |

06 Industry Application Scenarios

✔ Ground-mounted photovoltaic power stations in plains/hills

✔ Desert/tidal flat photovoltaic farm

✔ Utility-scale Photovoltaic park

07 Professional technical services

▶ Solution design and structural analysis:

Provide customized solution drawing, load calculation reports (including wind load/snow load/seismic force analysis) or assembly drawing.

▶ On-site survey:

Engineers conduct on-site investigations ground conditions with local soil investigation professionals.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site installation guidance to ensure safe and complete installation.

08 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

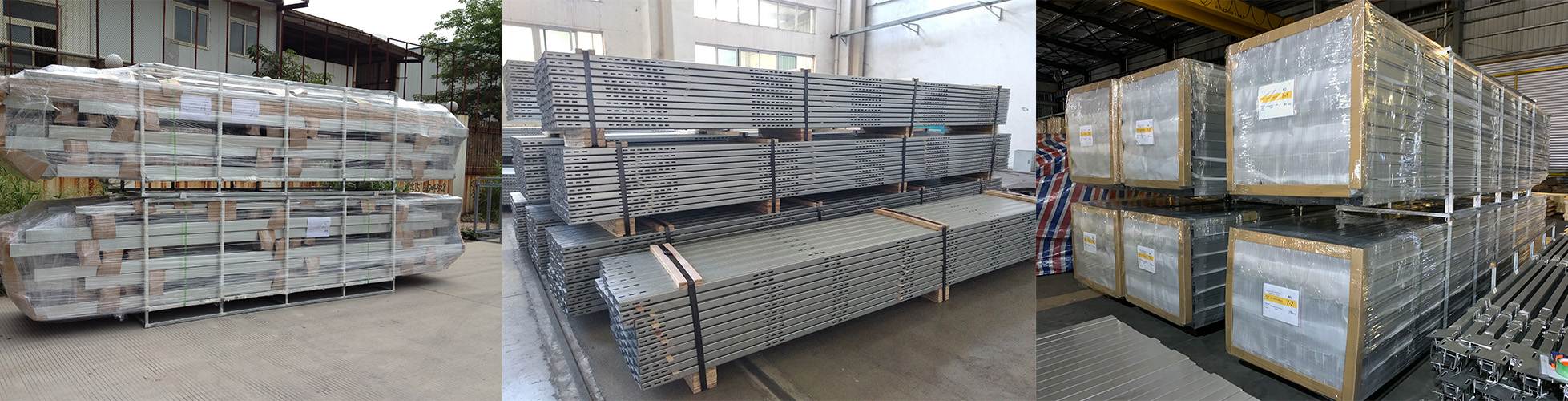

09 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

10 Project Case

leave a message

Scan to wechat :