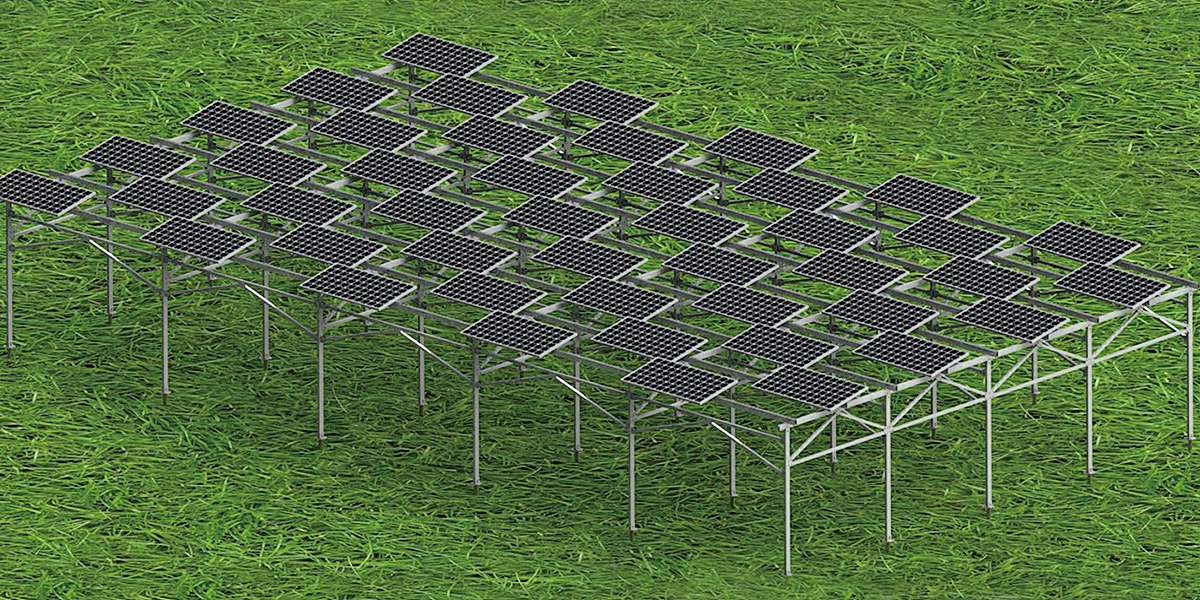

01 Product Description

An increasing number of farms and agricultural businesses are turning to solar energy to power their daily operations (such solar photovoltaic project is called "agrovoltaic", or "agrivoltaics"). The SF Agricultural Solar Mount offers a innovative solar ground mounting system that enables dual use of farmland—generating clean energy while continuing to support crop farming, livestock grazing, or greenhouse operations.

This agricultural solar mounting system is designed with flexibility in mind: it can be built tall to allow farming machinery to pass underneath, and spaced to let sunlight reach crops between rows of solar panels. For applications requiring full coverage—such as livestock shelters, fungi cultivation, or greenhouses—a completely waterproof and shaded structure can also be designed.

Constructed from high-strength anodized aluminum AL6005-T5 and stainless steel SUS304, the system provides excellent corrosion resistance and structural reliability, capable of withstanding wind loads up to 60m/s and snow loads up to 1.4 kN/m². The structural material can also be galvanized steel, or Zn-Al-Mg steel (or called ZAM, MAC) by similar structure. With screw pile or concrete foundation options, this farmland mounting structure is both easy to install and cost-effective.

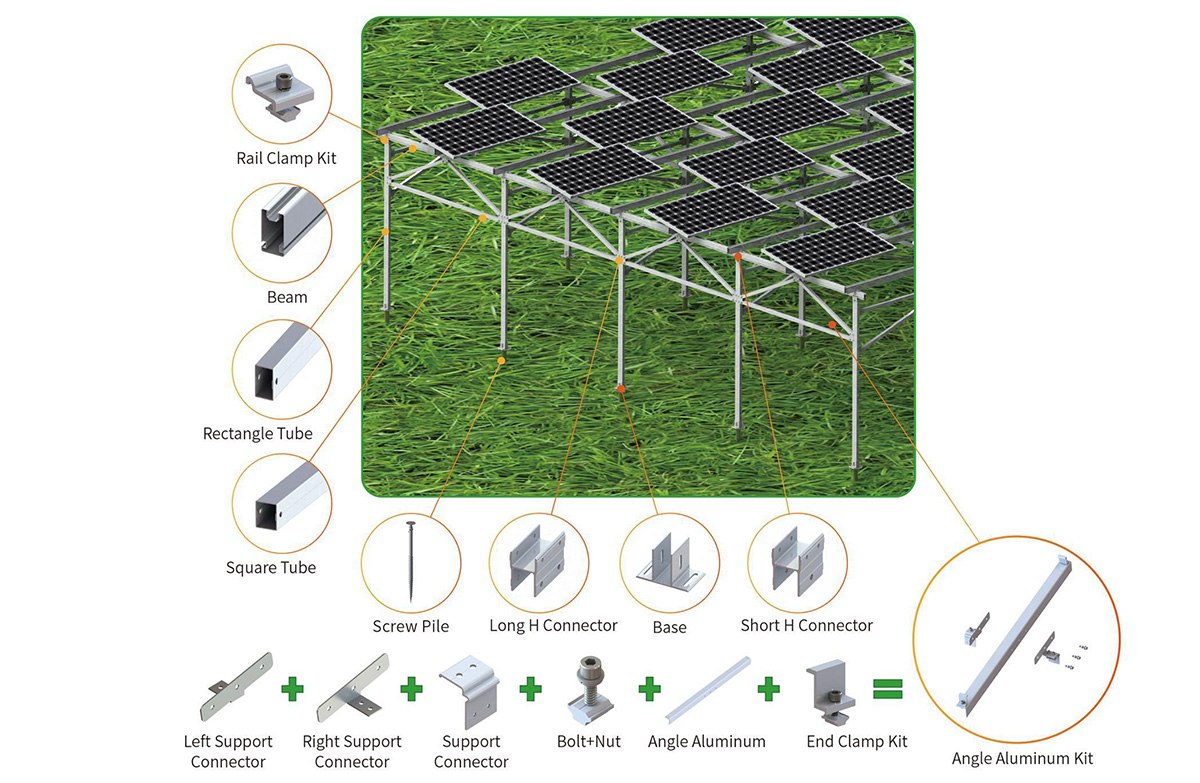

02 Accessory schematic diagram

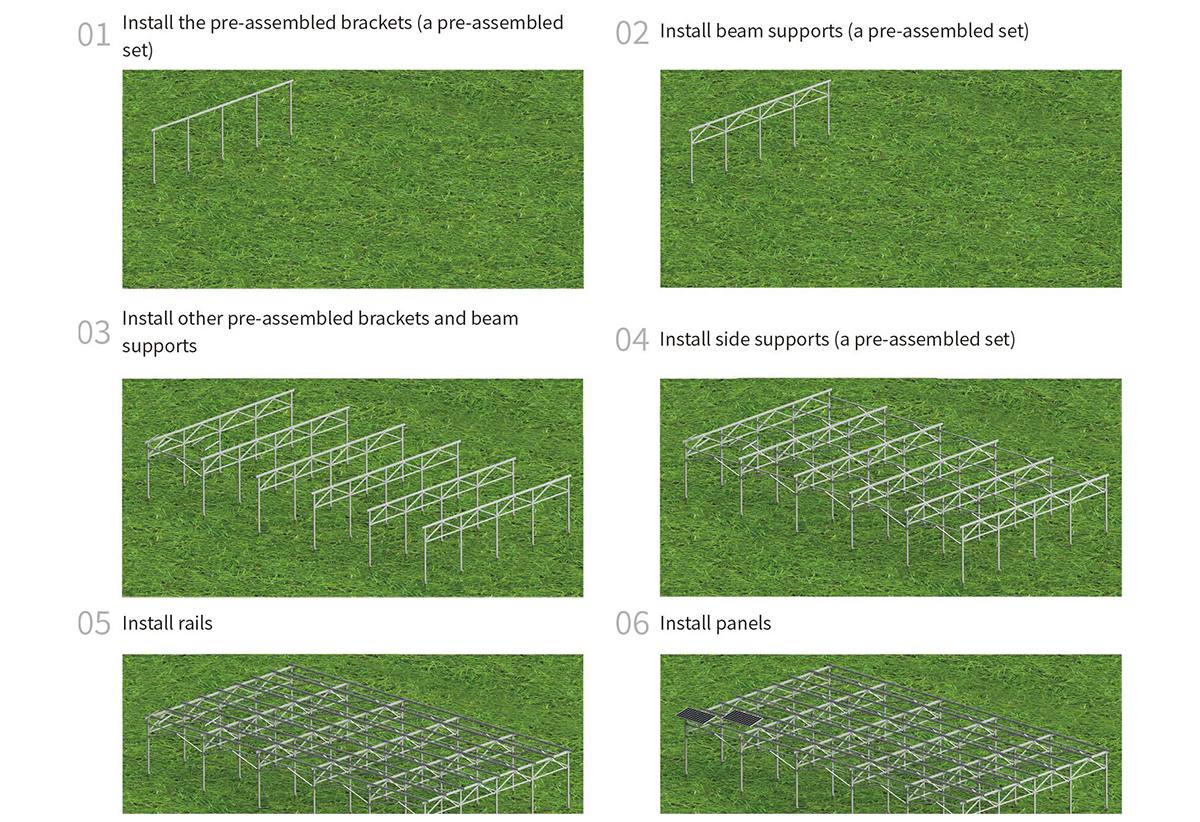

03 Installation steps

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Ground |

| Foundation | Screw Pile/ Concrete |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50429-2007 |

| Warranty | 10 Years Warranty |

05 Industry Application Scenarios

✔ Crop planting area in farmland (interrow light transmission)

✔ Livestock farms (full coverage of livestock sheds)

✔ Mushroom cultivation greenhouse (Shading and waterproof roof)

✔ Greenhouse photovoltaic integration

06 Professional technical services

▶ Solution design and structural analysis:

Provide customized solution drawing, load calculation reports (including wind load/snow load/seismic force analysis) or assembly drawing.

▶ On-site survey:

Engineers conduct on-site investigations ground conditions with local soil investigation professionals.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site installation guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

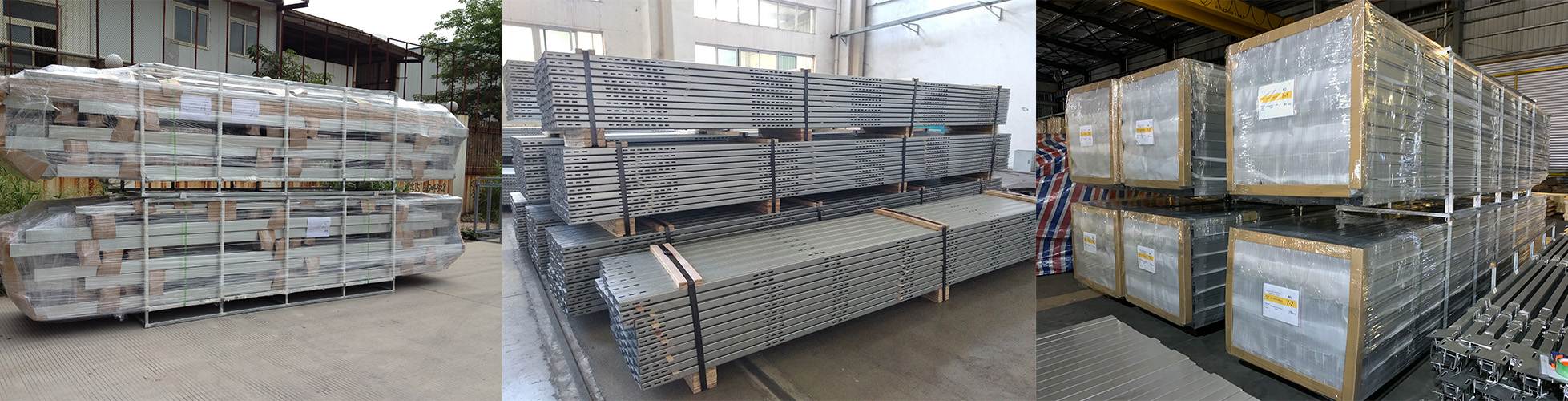

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :