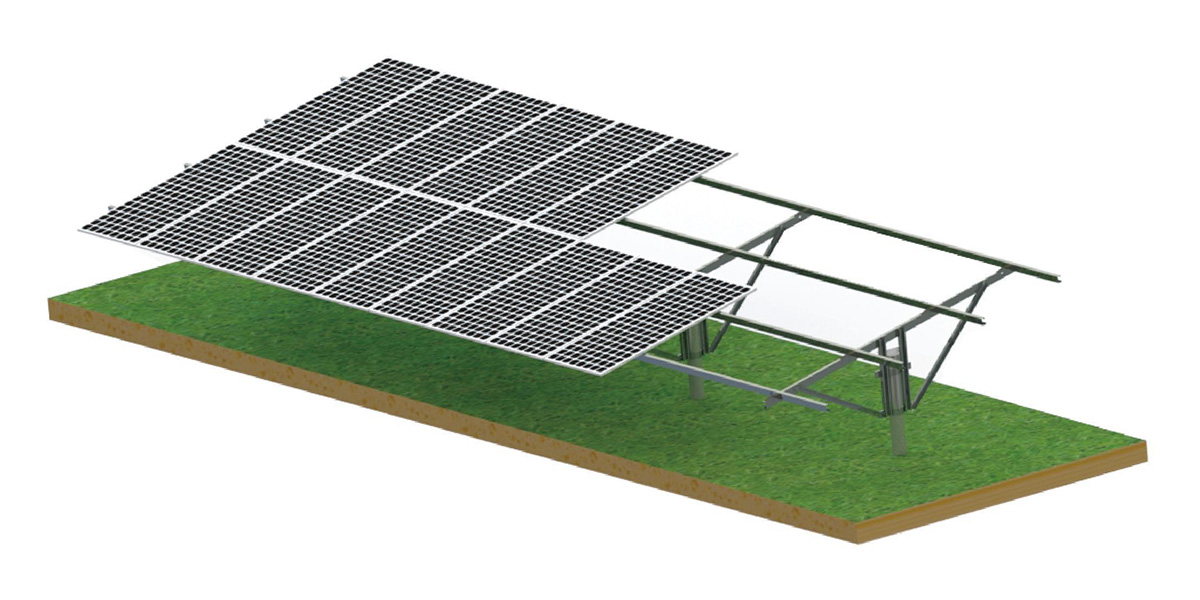

01 Product Description

SF PHC Pile Ground Mount-Steel offers a highly adaptable and eco-conscious solar mounting solution for large-scale and fishery-integrated PV projects. Utilizing pre-stressed high-strength concrete (PHC) spun piles as foundations, this system requires no earth excavation—minimizing environmental impact while providing exceptional stability across diverse terrains, including fish ponds, slopes, mud flats, and inter-tidal zones.

Designed to perform where traditional foundations cannot, the structure employs hot-dip galvanized steel or Zn-Al-Mg coated steel tailored to site-specific conditions, ensuring long-term corrosion resistance and structural reliability. With a wind load capacity of up to 60m/s and snow load resistance of 1.4 kN/m², this system meets rigorous international standards including GB, EN, and ASCE.

Easy to install and backed by a 10-year warranty, the SF PHC Pile Ground Mount combines cost-efficiency, minimal maintenance, and superior environmental adaptability—making it an ideal choice for utility-scale, commercial, and specialized solar installations.

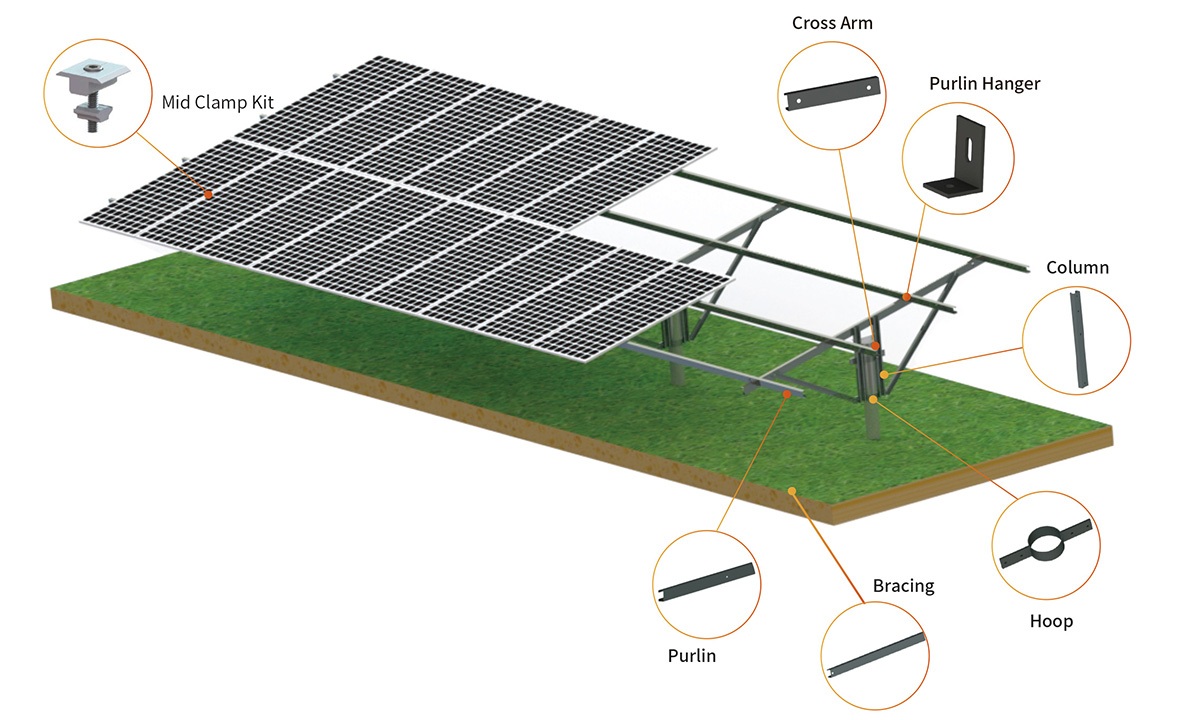

02 Accessory schematic diagram

03 Available Types of Columns

05 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Ground |

| Foundation | Pile Mount / High Concrete Pile (H≥600mm) |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Main material | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50017-2017 |

| standard | Anodized Aluminum AL6005-T5,Hot Dip Galvanized Steel, Zn-Al-Mg pre-coated steel, Stainless Steel SUS304 |

| Warranty | 10 Years Warranty |

06 Industry Application Scenarios

✔ Fishery pond surface Photovoltaic power Station (Fishery and Photovoltaic Complementary)

✔ Tidal flat/intertidal zone photovoltaic projects

✔ Mountain power Station

✔ Soft geological areas such as mudflats

07 Professional technical services

▶ Solution design and structural analysis:

Provide customized solution drawing, load calculation reports (including wind load/snow load/seismic force analysis) or assembly drawing.

▶ On-site survey:

Engineers conduct on-site investigations ground conditions with local soil investigation professionals.

▶ Installation training and guidance:

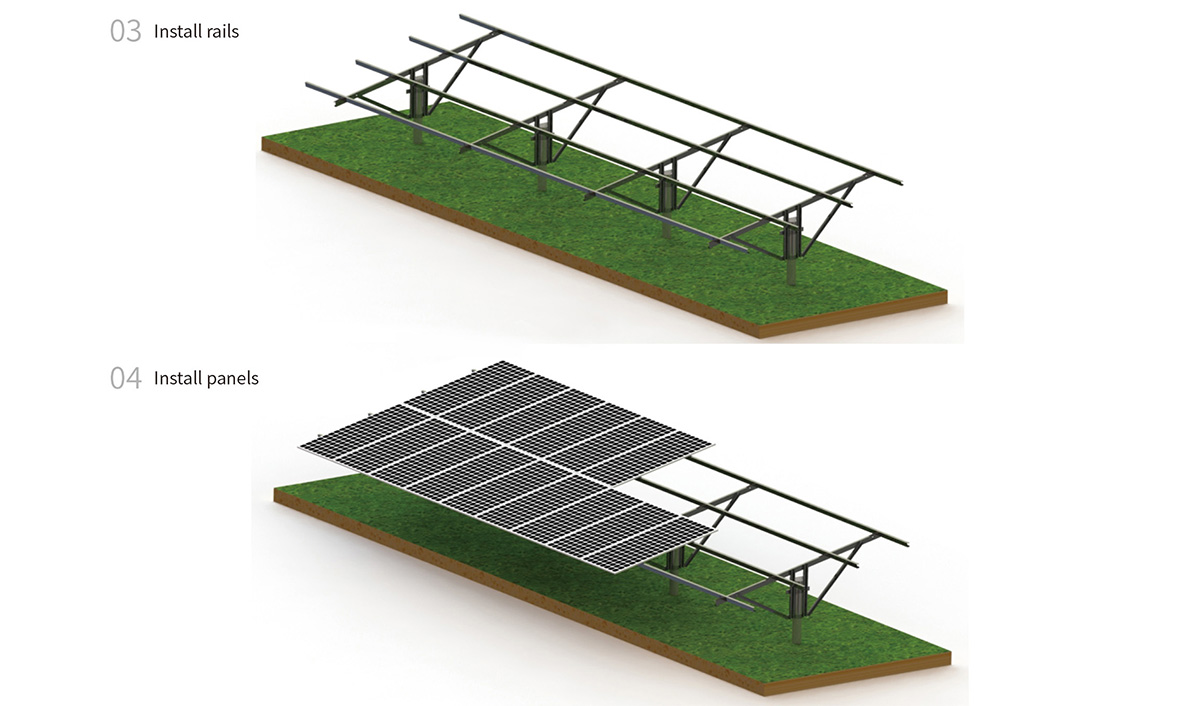

Provide installation videos, installation manuals and on-site installation guidance to ensure safe and complete installation.

08 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

07 Technical verification system

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

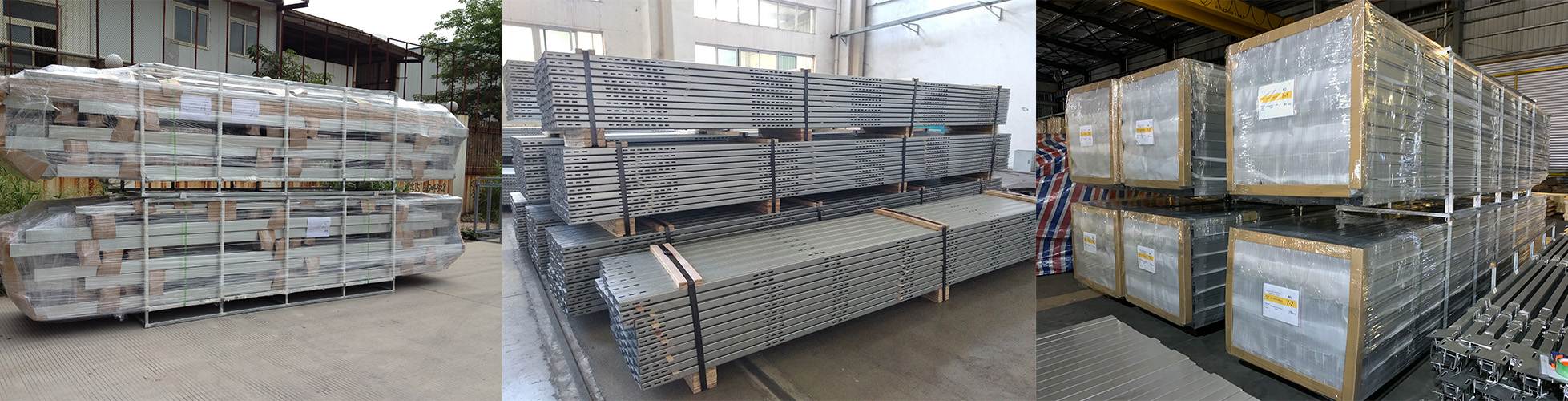

09 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

10 Project Case

leave a message

Scan to wechat :