The Klip Lok Solar Metal Roof Mount is a professionally engineered, high-strength aluminum solution designed for a secure and precise connection to metal roof sheets. Its optimized design significantly reduces installation time and overall cost.

Color :

Silver blackMaterial :

AL6005-T5Certification :

ISO,SGS01 Product Description

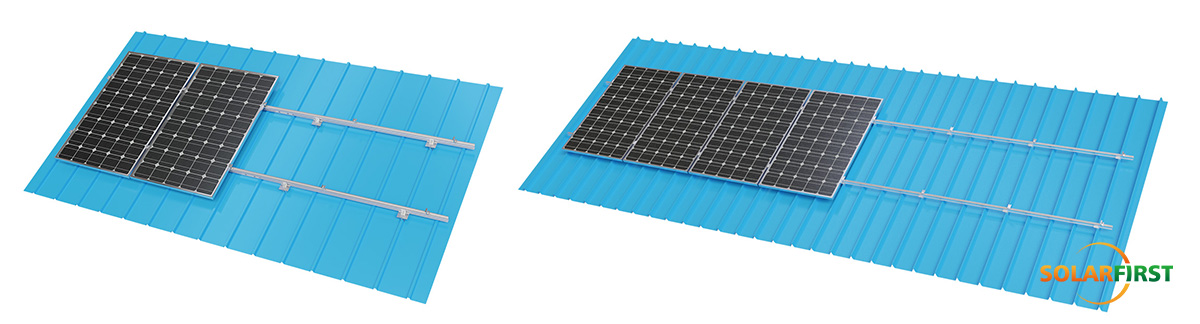

This non-penetrating mounting system is engineered for Klip Lok metal roofs, offering a streamlined and cost-effective solution for solar panel installation.

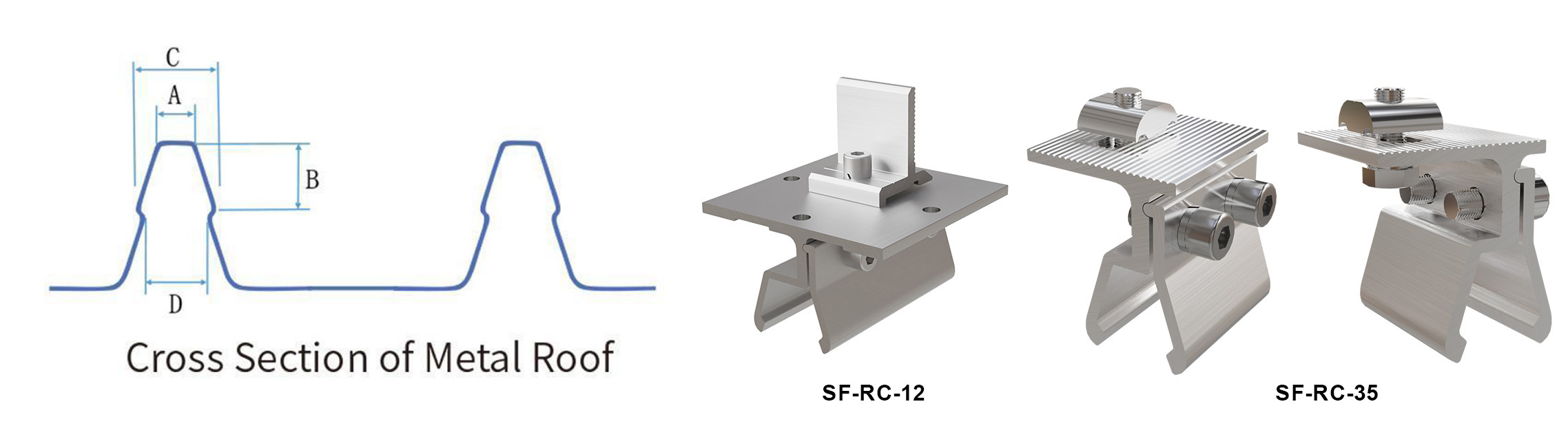

Its lightweight aluminum construction minimizes additional stress on the underlying roof structure. Specialized clamps are tailored to fit specific Klip Lok sheet types, while optional L-foot brackets provide added elevation where needed.

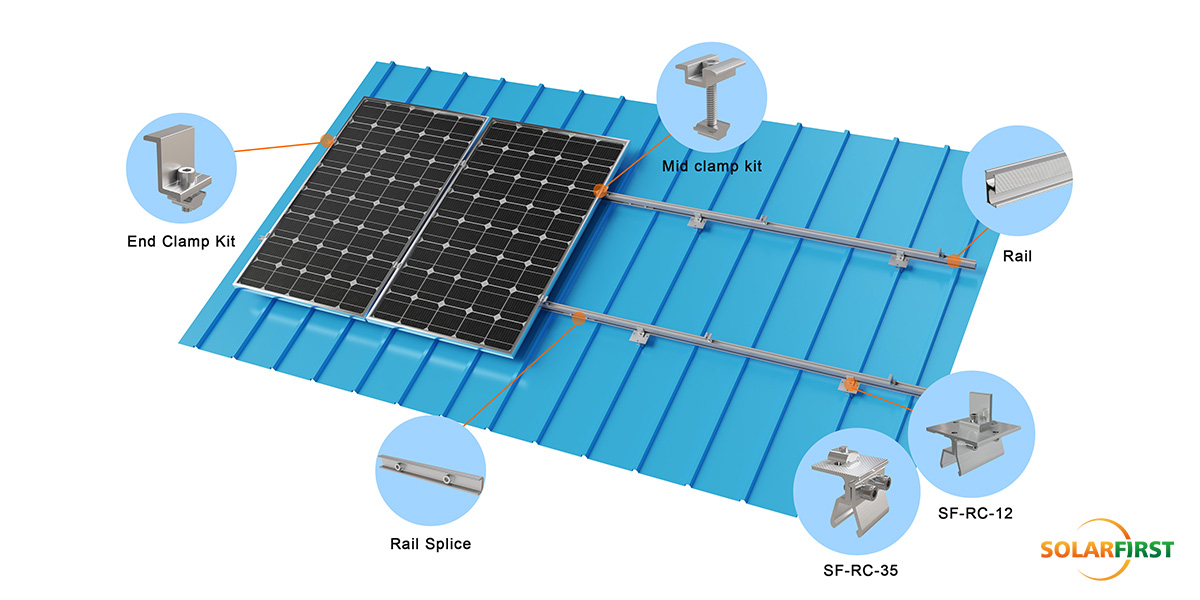

02 Accessory schematic diagram

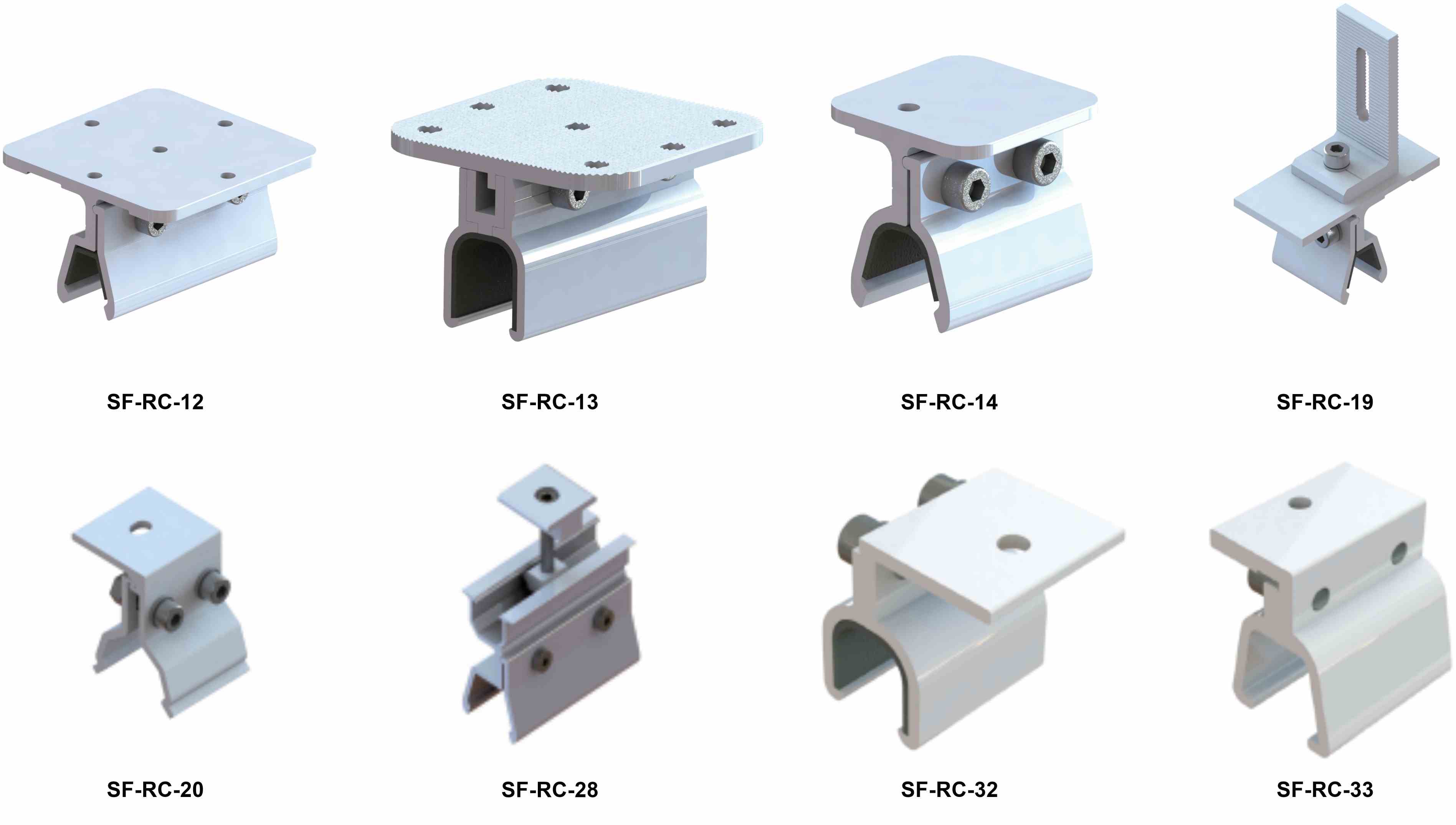

03 Product Components

04 Core Engineering Parameters

| Key indicators | Parameter details |

| Applicable roof | Metal roof (Klip Lok type) |

| Wind load | 60m/s |

| Snow load | 1.4 kN/m² |

| Tilt Angle | Parallel to the roof |

| Main material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304 |

| standard | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50429-2007 |

| Warranty | 10 Years Warranty |

05 Applicable scenarios

✔ Manufacturing factory: Roof of automotive/electronic factory buildings

✔ Cold chain logistics center: Large warehouse roof

✔ Agricultural greenhouse upgrade: Light steel frame greenhouse

06 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

07 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

08 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :