01 Product Description

SF-PVROOF01 BIPV Roof Skylight seamlessly merges natural daylighting with solar energy generation, offering an elegant and eco-functional alternative to traditional skylights. Designed for both aesthetic harmony and high performance, this system provides waterproofing, wind and snow resistance, and optimal light transmission—transforming roofs into efficient, dual-purpose power generators.

A standout feature of the SF-PVROOF01 is its customizable light transmittance, ranging from 10% to 80%, making it ideal for applications from bright commercial atriums to softly lit residential spaces. The anti-ultraviolet co-extruded layer not only converts UV light into visible light but also provides temperature insulation, supporting plant growth in greenhouses and enhancing indoor environmental quality.

Engineered to withstand snow loads up to 35 cm and wind speeds of 42 m/s (EN13830 compliant), this system is both versatile and highly durable. It is suitable for a wide range of applications including greenhouses, villas, pavilions, bus stations, and commercial buildings, and can be integrated with skylights, steel frames, or conventional wooden structures.

SF-PVROOF01 combines innovative energy technology with architectural elegance—a smart, sustainable choice for modern building-integrated solar solutions.

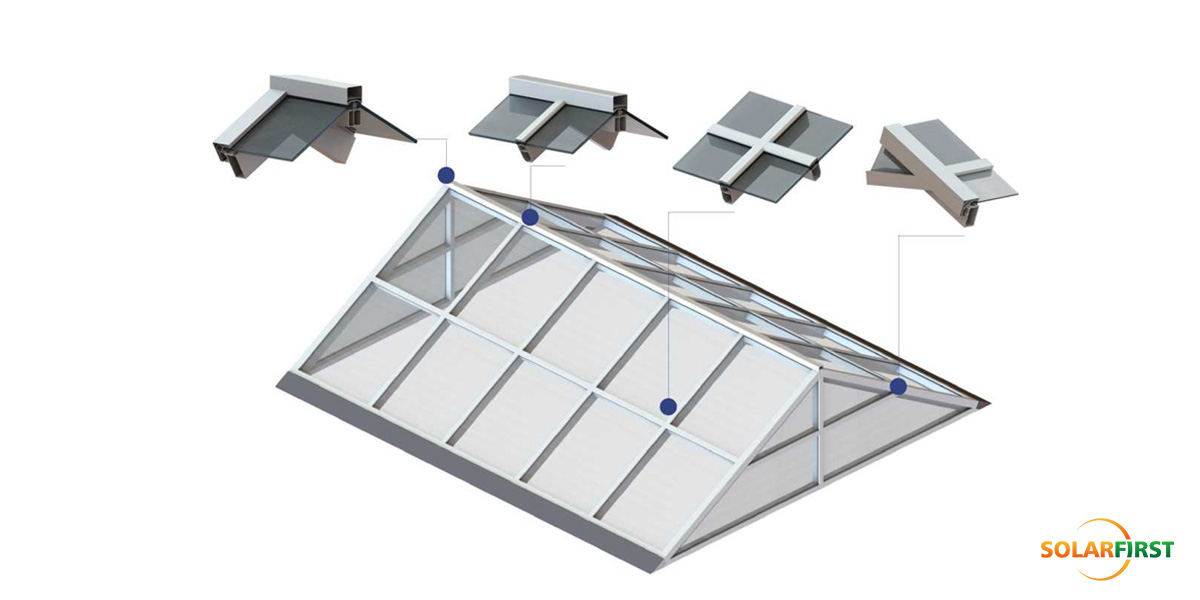

02 Accessory schematic diagram

03 Core Engineering Parameters

| Key indicators | Parameter details |

| Installation | BIPV Roof |

| Wind Load | up to 60m/s |

| Tilt Angle | ≥3° |

| Snow Load | 1.4kn/m² |

| Standards | GB50009-2012, EN1990:2002, ASCE7-05, AS/NZS1170, JIS C8955:2017,GB50017-2017 |

| Material | Anodized Aluminum AL6005-T5, Stainless Steel SUS304, Hot Dip Galvanized Steel |

| Warranty | 10 Years Warranty |

04 Industry Application Scenarios

✔ Greenhouse agricultural shed

✔ The top floor of a civilian house or villa

✔ Business floor

✔ Outdoor pavilion

✔ Bus stop shelter

05 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

06 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

07 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

09 Project Case

leave a message

Scan to wechat :