01 Product Description

Solar First introduces its robust Solar Ground Screw Pile Foundation Screws, engineered to deliver lasting stability and reliable support for photovoltaic installations across diverse terrains. Crafted from Q235 carbon steel with a high-quality hot-dip galvanized coating exceeding 80μm, these screws offer exceptional corrosion resistance and durability even in challenging environmental conditions.

The customized production approach allows the system to meet unique foundation requirements, making it ideal for a wide range of solar power station projects. Whether for rocky, uneven, or soft soils, Solar First’s screw pile foundation design ensures quick installation and long-term performance.

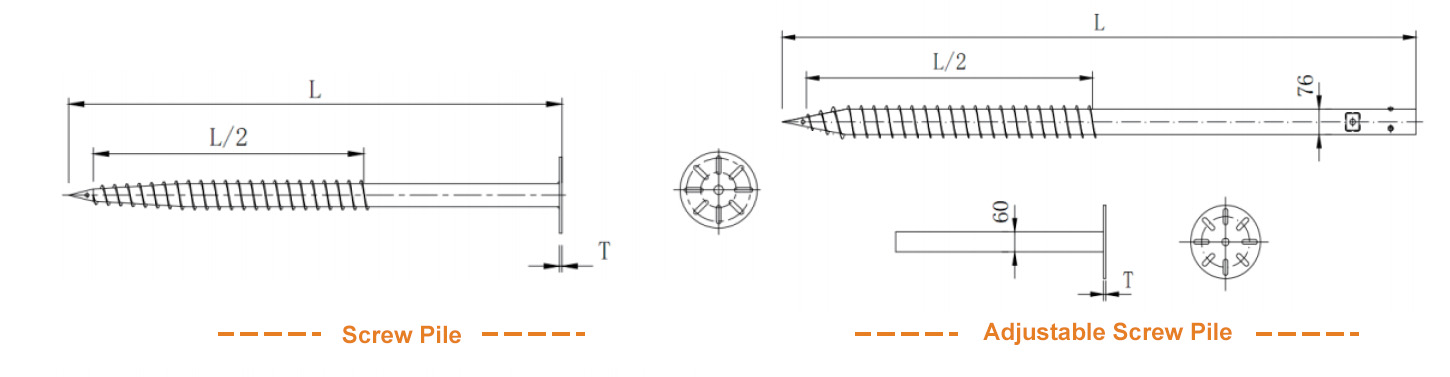

02 Accessory schematic diagram

03 Construction

04 Industry Application Scenarios

✔ Ground-based centralized power stations: Suitable for large areas of flat or gentle slope terrain, the installation speed of spiral ground piles is fast (no concrete curing is required), significantly shortening the construction period.

✔ Agricultural photovoltaic complementary/fishery photovoltaic complementary project: The pile body is deeply underground, causing little disturbance to the soil and not damaging the plough layer or aquaculture water area.

✔ For soft geological conditions such as sandy land and tidal flats: Use extended spiral blades (with a depth of over 3 meters) to increase uplift resistance.

✔ Mountainous and hilly areas: Adjustable height helical piles adapt to the slope and keep the components flat.

05 Professional technical services

▶ Scheme design and structural analysis:

Provide professional solution drawings, structural analysis reports, installation manuals, or assembly drawings.

▶ On-site survey:

Engineers conduct on-site surveys of the roof conditions to confirm installation conditions and risk points.

▶ Installation training and guidance:

Provide installation videos, installation manuals and on-site technical guidance to ensure safe and complete installation.

06 Technical verification system

Provide standardized installation videos, operation manuals and on-site technical guidance to ensure zero error in construction.

▶ Extreme environmental testing

• Pass the low-temperature impact at -40℃

• Salt spray corrosion (3,000 + hours)

• Extreme tests such as 60m/s hurricane simulation.

▶ Third-party certification

• We hold wind pressure, snow pressure, seismic resistance and material certification certificates issued by TUV, SGS and other institutions to ensure the compliance of global projects.

07 Packages & Shipping

International standard packaging; Goods are dispatched from Shanghai, Ningbo, Tianjin, Xiamen and Shenzhen ports in China.

08 Project Case

leave a message

Scan to wechat :